Celebration of Structure

Specialty structures tend to leave nothing to the imagination. The structure, connections, and finishes of all components are visible, making establishing expectations early a critical step for the project team. A common example of this is defining the level of architecturally exposed structural steel required. Attention to detail is the name of the game. Excellent examples of this are the 34th Street MTA Canopies as well as the Howard Hughes Research Institute.

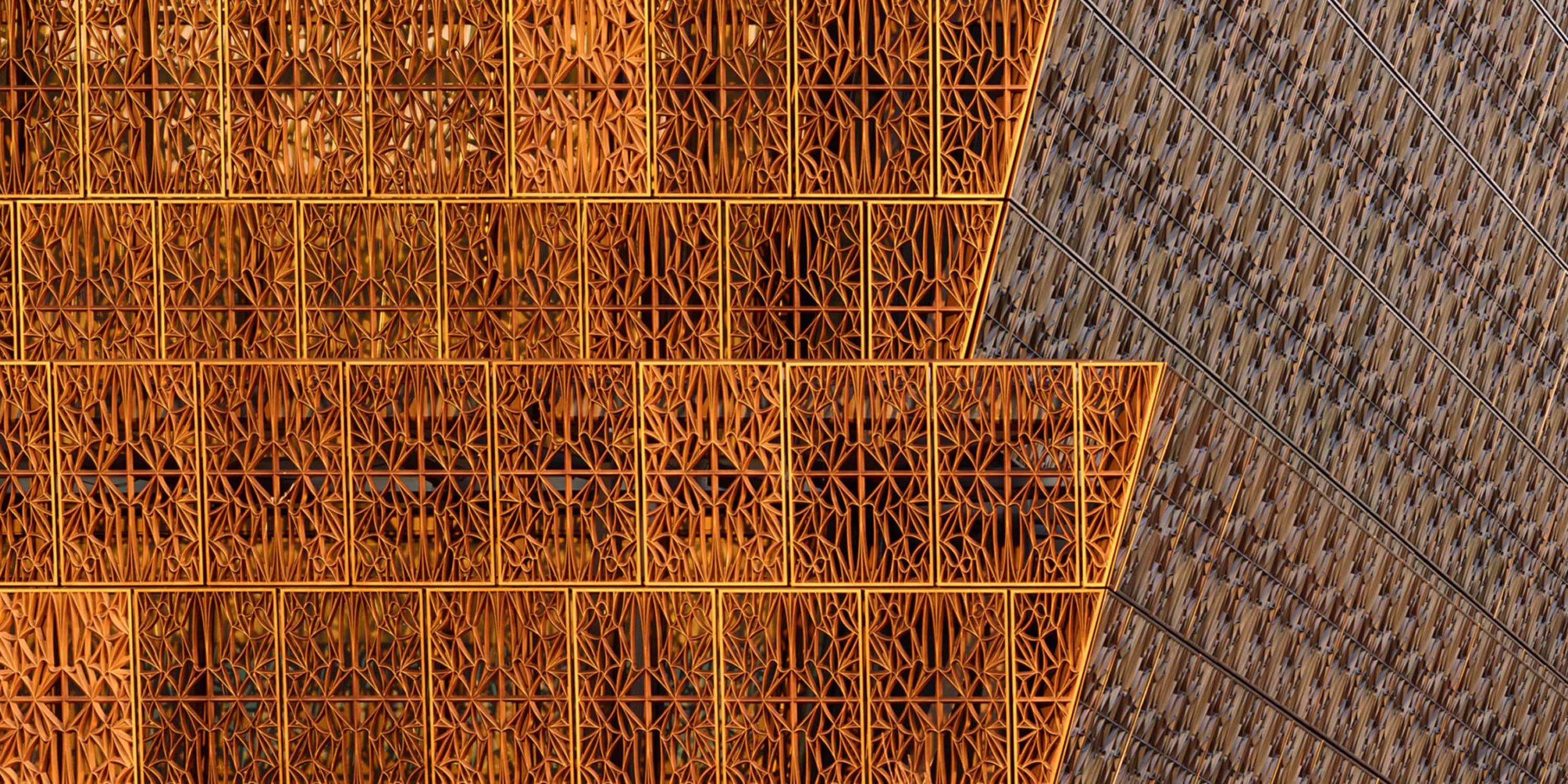

AESS Structure Takes Center Stage

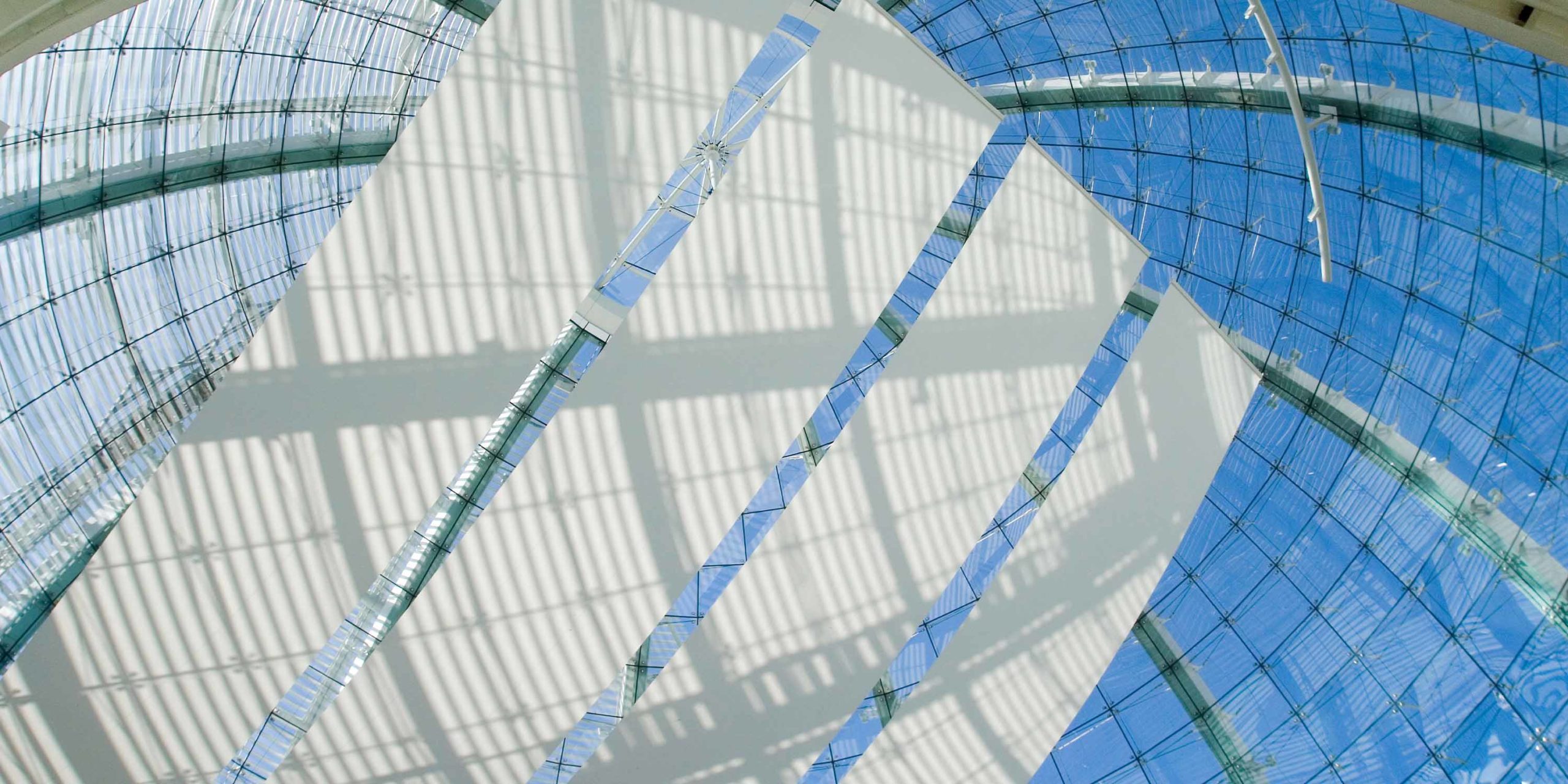

The L.A. Live Podium uses a combination of tall-span architecturally exposed structural steel, tension rods and cables, glass fins, stainless steel fittings, glass bolts, and point-fixed clamped features along the main south, north and west entryways.

AESS Structure Takes Center Stage

The south Podium has the greatest span and requires a deeper truss assembly. Coordinating expectations of weld and finish quality with the architect early on is key to the success of delivering a wall with architecturally exposed structural steel.

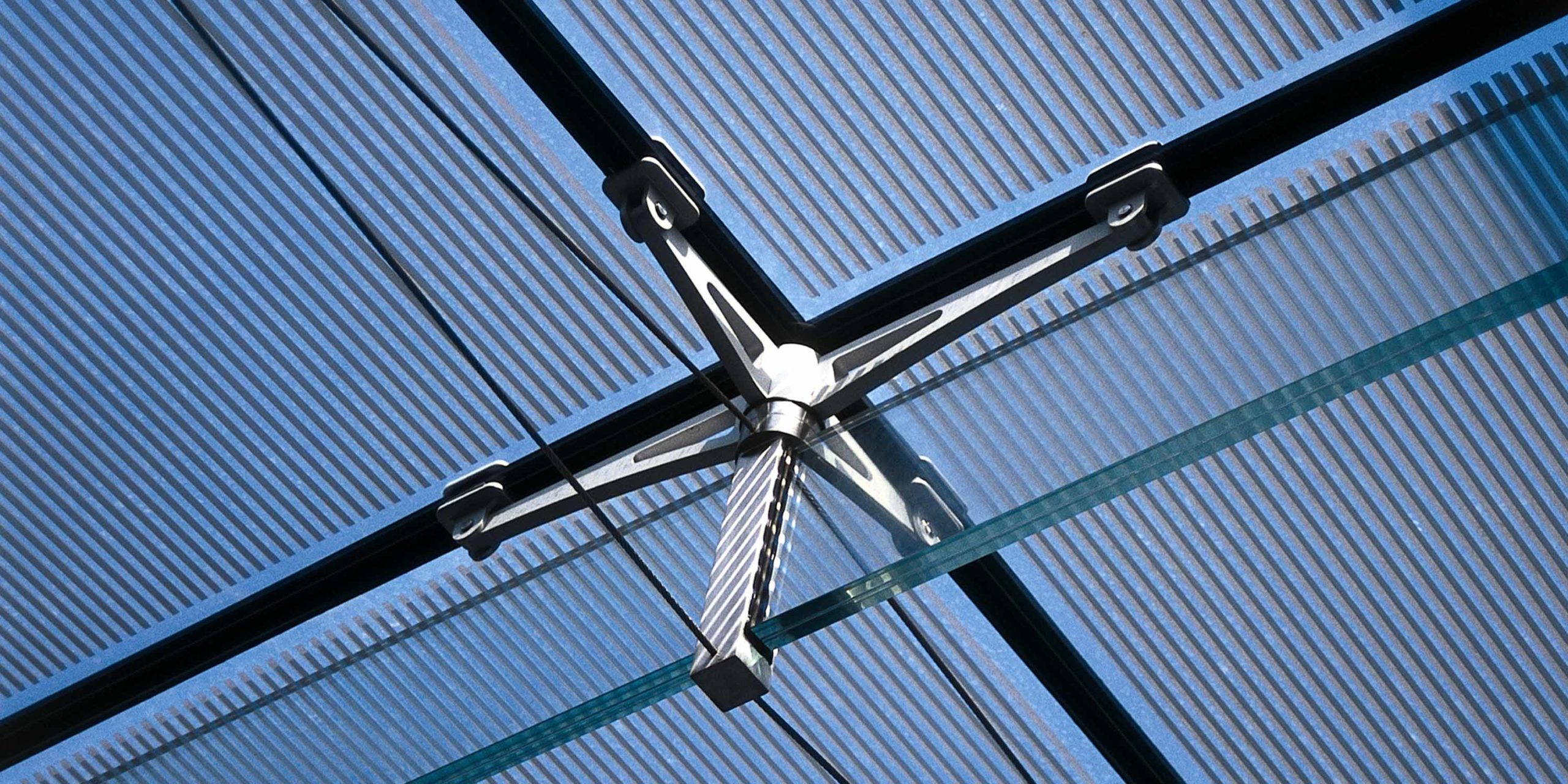

Point-clamped Connection to Frameless Glass

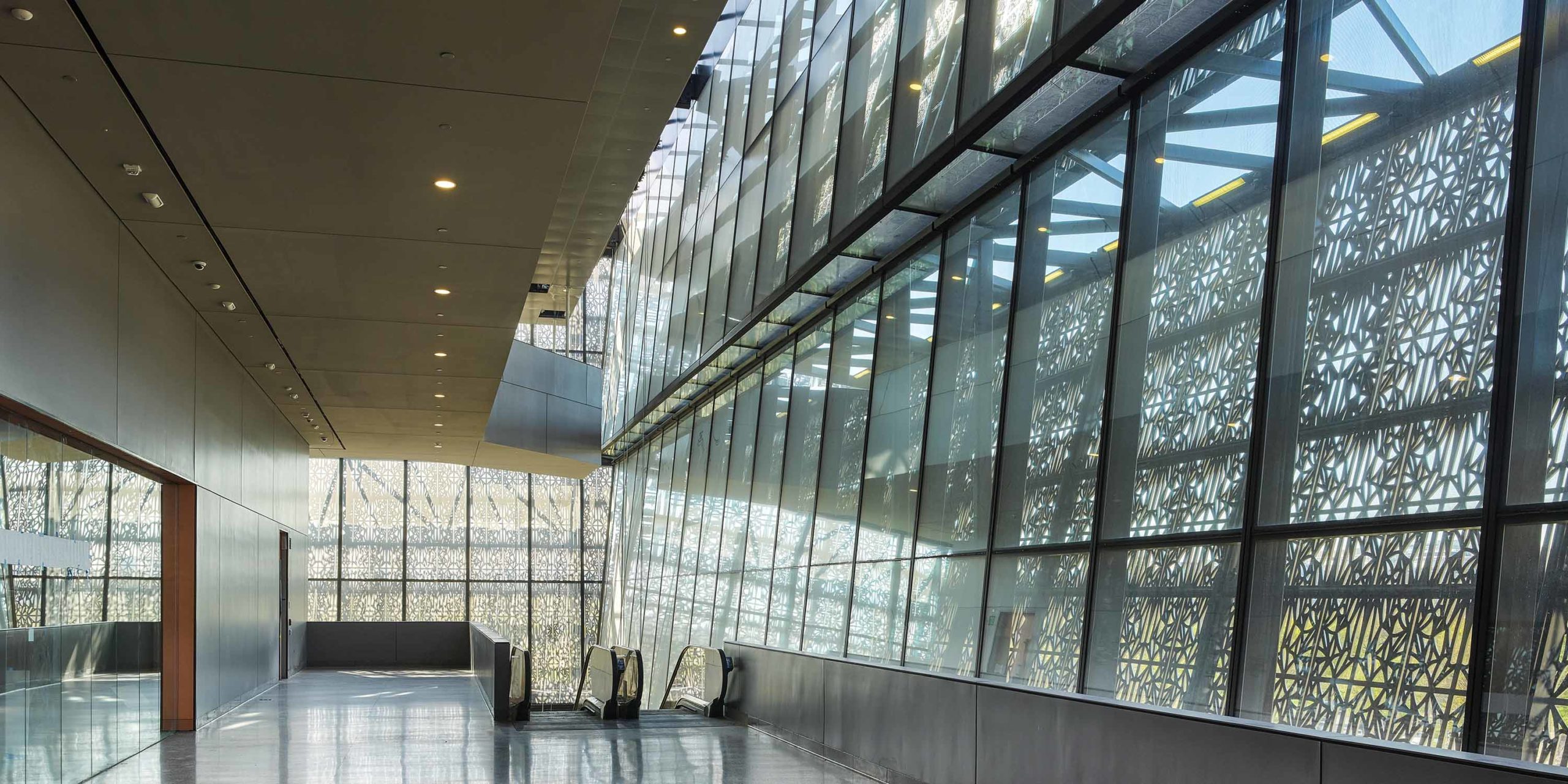

From the truss, a pair of custom stainless steel fittings are bolted, reaching outwards to capture the laminated glass lites along the horizontal glass joint. The clamped capture transfers loads imposed upon the glass through the fitting arms back to the steel truss.

Dramatic Results

The L.A. Live Podium entryways are a celebration of structure that compliments the goals of maximizing transparency. The results are a lobby space flooded with daylight by day, and a beacon at night, making the space an extension of the urban landscape.

Complex Geometry and Tools to Adapt

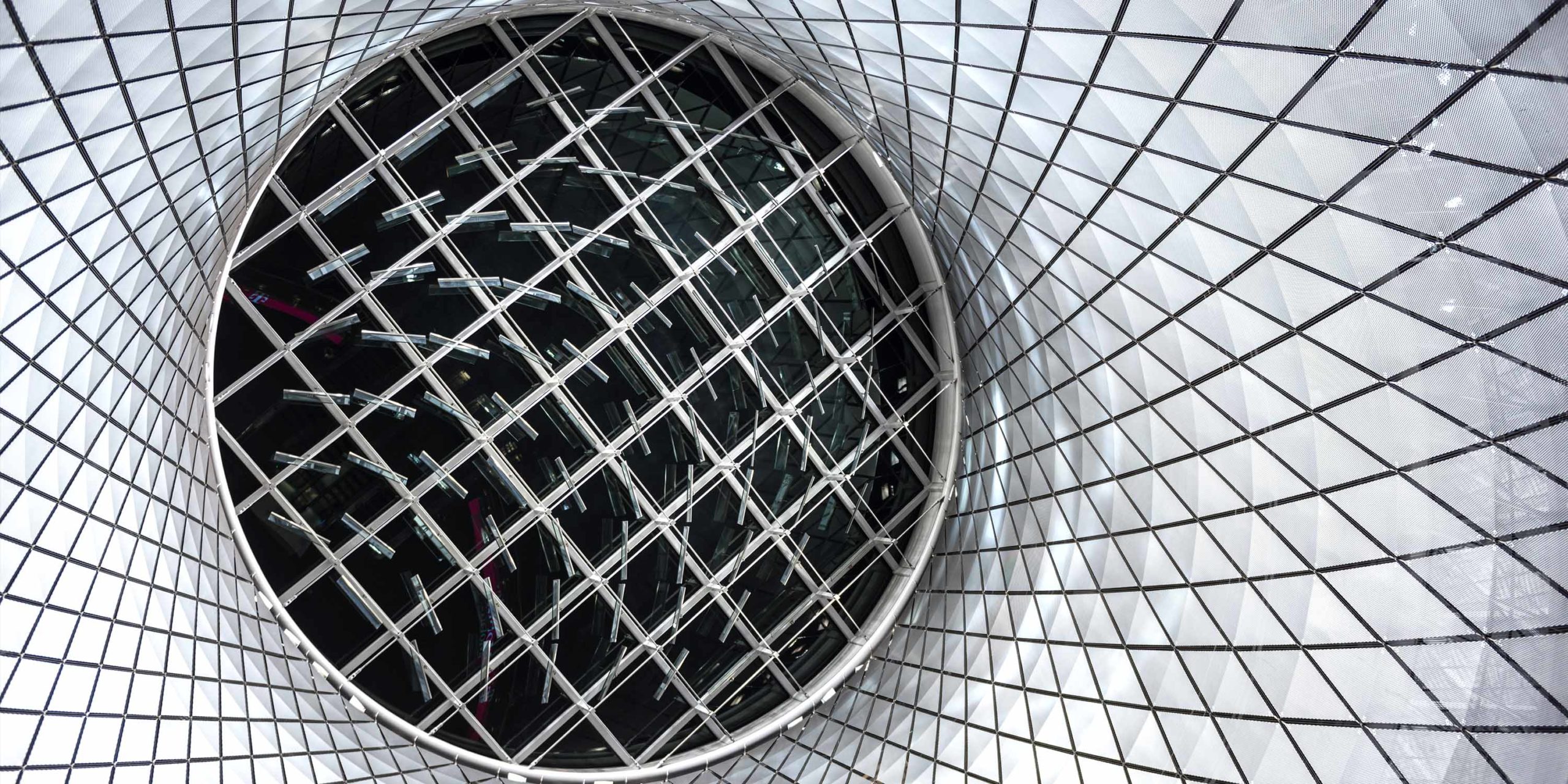

Excellent examples of complex geometry at a large scale include Chase Center Arena, The Spheres at Amazon, and VIA57 West. Parametric models are used from design through construction on these projects as they provide flexibility to apply design logic to infinitely unique panel variations. In addition to different modeling tools, these enclosure systems require different manufacturing processes, quality control precautions such as laser scanning, and extreme education of field crews to install these systems with precision safely.

watch video

Parametrically-driven architecture requires an integration of advanced 3D tools at every step of the facade’s delivery. The Amazon Spheres‘ enclosure utilized Rhino and Grasshopper to automate drawing development. In manufacturing of the AESS steel frames, laser scanning was employed to ensure precision. Ultimately, this accuracy in process allowed field crews to install mega-pentagonal frames with the glass already mounted on the steel for a dramatic installation sequence.

Emerging Materials

Despite Enclos’ association with aluminum and glass curtainwall, at the core is truly a company focused on custom enclosures, indifferent to any one material or approach. We understand the need to be adaptable and have taken the initiative to have on-going research into emerging material technologies. For example, this initiative was a differentiator in our collaboration to introduce the largest architectural fiber-reinforced polymer in North America at the time in the San Francisco Museum of Modern Art.

Maximizing prefabrication, along with safe, efficient installation, are the top priorities for Enclos. When architects imagine enclosures that go beyond glass and curtainwall, the results can be facades of distinction.

watch video

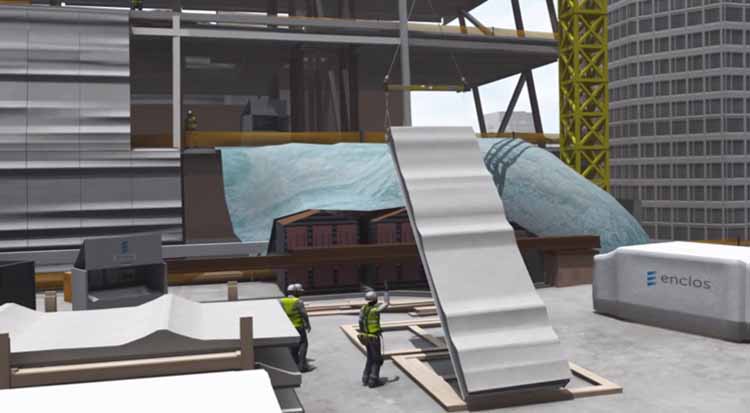

Simulated Manufacturing of Unitized FRP

Emerging materials have the ability to take shapes not readily achievable with glass. Such is the case with fiber reinforced polymers (FRP) that is a molded material that, when combined with CNC milling technology for the molds, leads to endless geometric possibilities as a rain-screen panel for architects. The SFMoMA feature wall creates an organic, ripple effect that was the largest architecturally application of FRP in North America at its time of completion.

No matter the material, no matter the scale nor complexity, a spirit of rising to the challenge has positioned Enclos to bring your next specialty vision to life.