At the core of Enclos is a spirit of rapid adaptability. This is most apparent in a nimble approach to manufacturing. The top priority for Enclos is quality, and this is no more evident than in our mission to maximize the number of weather seals that are executed in an environmentally controlled shop rather than on a project site. This step occurs during assembly when pieces of glass are structurally silicone glazed (SSG) to aluminum frames. It is not uncommon for Enclos to establish a new assembly shop near a large project, or thriving market, to execute the assembly phase of a project, resulting in minimal transit to the site. As an alternative to using an Enclos facility, the opportunity exists to supplement our manufacturing production to align with a project’s goals such as expedited schedule, economy, and proximity to the site. Enclos partners with a trusted network of pre-qualified suppliers to provide clients with the best of both worlds: in-house or outsourced; domestic or global.

Delivering Luxury to An Island

Building a high-end building facade in Honolulu, thousands of miles from the nearest shores, requires serious coordination and dependency on a global supply-chain, including high-end glass from Germany. Enclos’ operations were up to the task, successfully getting nearly 112,000 loose parts to Hawaii for integration into the facade.

Materials

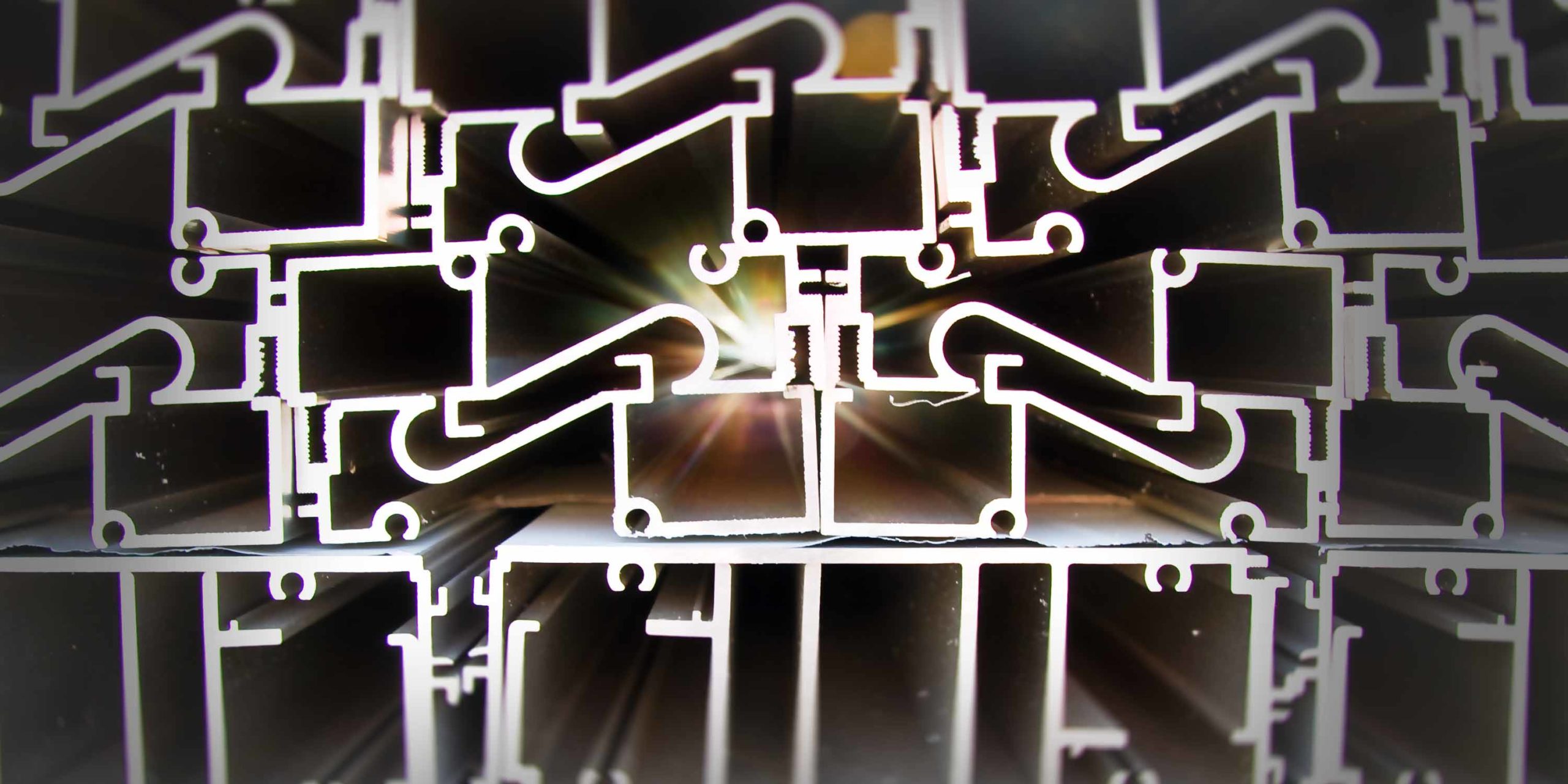

The innumerable materials finding their way into unitized building enclosures increasingly goes beyond glass alone. Transparent, opaque, flat, curved, natural, manufactured, extruded, molded, cast, perforated—you name it. Each may be selected from material experts both domestically and abroad. Enclos has successfully provided project materials and services from diverse areas of Europe and Asia on dozens of domestic projects, saving our clients many millions of dollars in the process. In circumstances where domestic supply is a requirement, Enclos has both dedicated internal manufacturing facilities and qualified suppliers stateside.

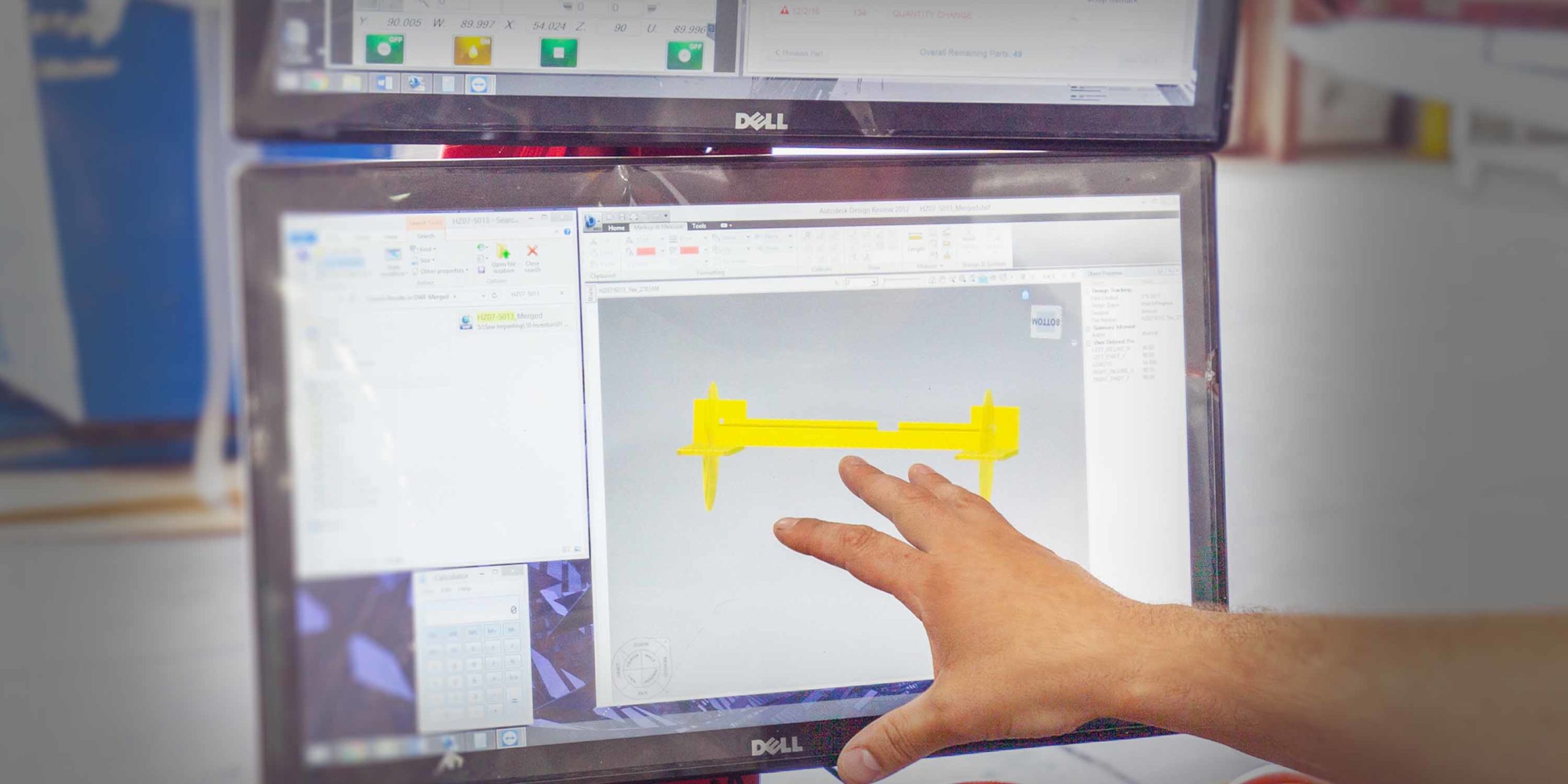

Fabrication

In curtainwall, fabrication refers to the making and modification of materials, primarily the floating of glass lites, extruding of aluminum for frames, and CNC modification of those extrusions. Enclos limits its in-house fabrication to the latter, utilizing a collection of sophisticated CNC machines that allow for a direct file-to-fab workflow.