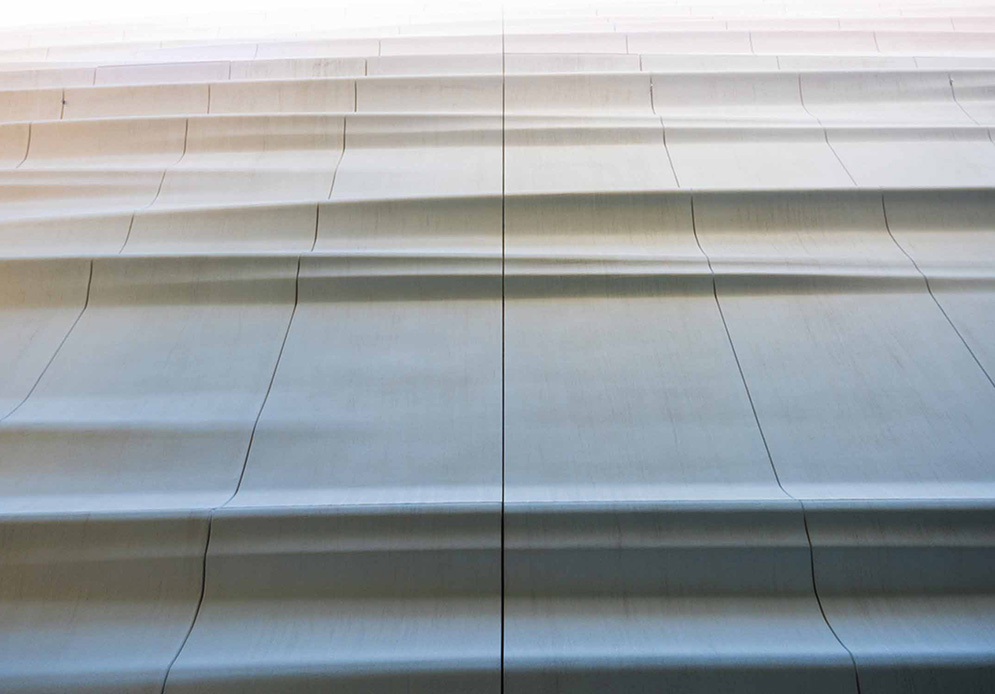

Chasing Vision

The New Embassy of Australia in Washington D.C. was a unique and demanding project with an Australian voter-approved budget and a complicated facade that integrated highly topographical copper panels. As the facade contractor, Enclos participated in a collaborative and successful design assist phase which set up the project for success and delivered a beautiful facade that met the design intent and kept the project budget intact. This paper looks at the design assist process through three distinct lenses directly related to the New Embassy: facade typology and topography, infill materiality – specifically copper, and design decision planning and tracking.

read more

Custom Curtainwall

Curtainwall is a prefabricated, modular approach to cladding large buildings. Curtainwall systems are typically “hung” from the building structure, attached to the floor slabs, and do not carry any dead loads imposed from the building structure. The units are designed to support their self-weight and to transfer horizontal loads (wind) incident upon them to the primary building structure. Special design considerations can include daylighting, thermal, acoustical, security, and blast-resistant performance. Curtainwall designs for large buildings are almost always custom to individual project requirements.

read more

Specialty at all Scales

Enclos has a rich history of completing specialty enclosure systems that fall outside the mold of unitized curtainwall. For some projects, there is a specialty feature—perhaps a glass jewel box element or feature lobby wall—that is within the enclosure scope of work that is in addition to the curtainwall. On other projects, the entire scope is solely a specialty system. Whichever the case, whatever the scale, if it is a challenging structure for a project team that values quality and technical excellence, Enclos is up to the challenge.

read more