300 New Jersey Avenue is a state-of-the-art office building in Washington, D.C., located just one block from the U.S. Capitol. The project includes the construction of a new centerpiece atrium that connects two existing office buildings and is the first office building by London-based Rogers Stirk Harbour + Partners and Pritzker Prize winning Principal Richard Rogers.

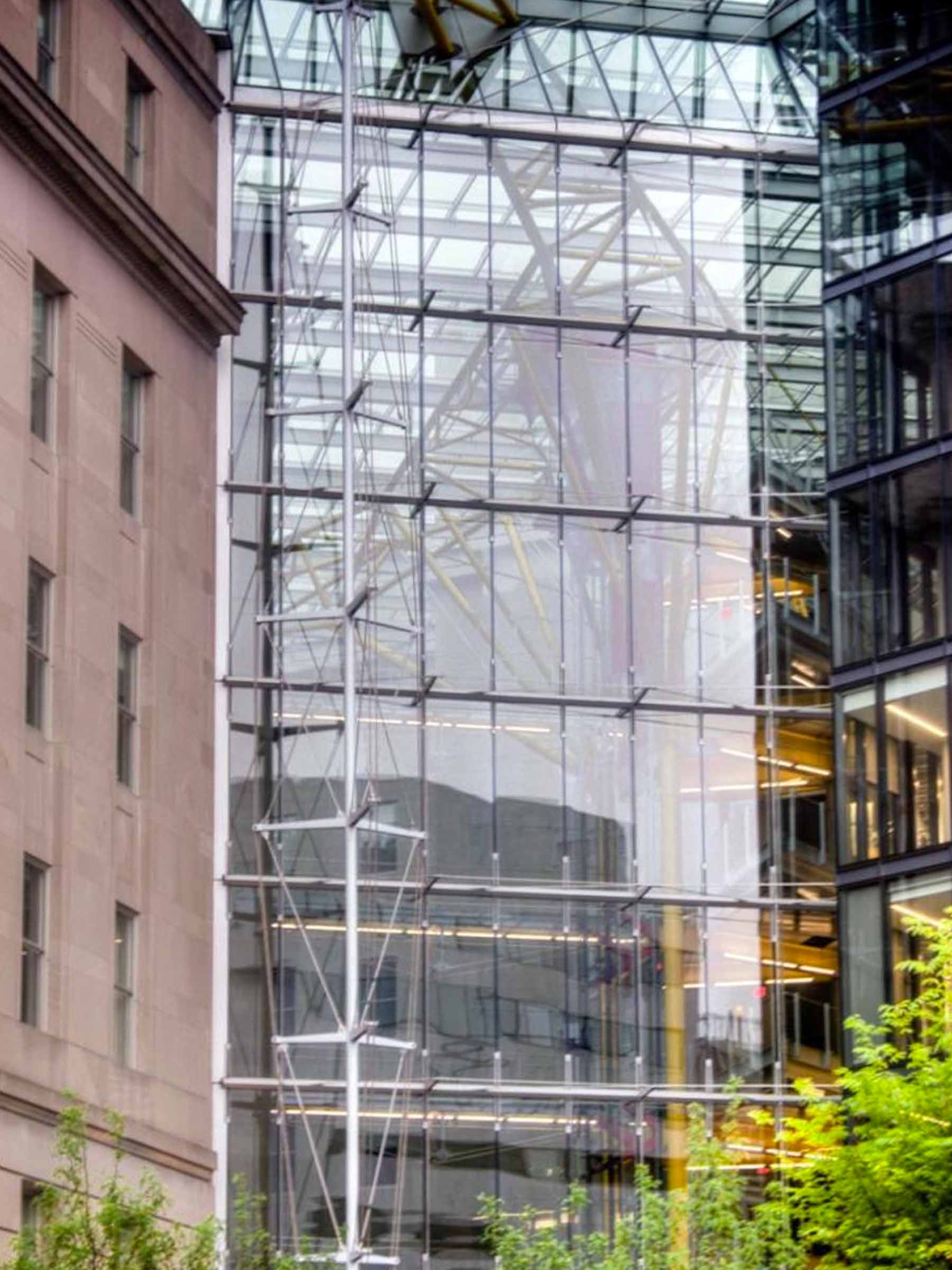

Enclos was responsible for the challenging facade program that encloses the new 10-story atrium space. A yellow tree-like AESS steel construct provides the atrium’s vertical structure, supporting a trapezoidal flying glass roof in addition to carrying exposed HVAC and other building system components. Multiple levels of sky bridges tie the complex together. With all structure and systems being exposed, the highest level of craftsmanship was required for every aspect of the project.

Structural Glass Bridges the Old and New

Enclos was responsible for the architecturally exposed structural steel (AESS) scope and glazing systems for the vertical atrium wall, sloped transition wall, overhead skylight and louver systems that create the 10-story atrium space. Each of these systems spans between an existing historic structure and a newly constructed office building. Achieving the enclosure required coordination of existing anchorage points to the historic structure with diligent surveying, and connection details that permitted differential movements between the old and new structures.

Circulation Takes Center Stage

The function of the atrium space includes connecting the existing structures and the new office building with a circulation core including glass bridges extending out from the central elevator rise. The yellow tree structure supports both the circulation core and gravity connections for intermediate points of the skylight spans.

The skylight itself is a series of steel ladder frame trusses that support an aluminum glazed skylight system with integral gutters between the ridge and valley profile of the overhead surface. The skylight glass includes a dot-frit pattern to mitigate solar heat gain.

Accommodating Differential Movement

The function of the atrium space includes connecting the existing structures and the new office building with a circulation core including glass bridges extending out from the central elevator rise. The yellow tree structure supports both the circulation core and gravity connections for intermediate points of the skylight spans.

The vertical atrium wall is entirely dead-loaded back to the new construction by eight tension rods – four inside and four outside – up to 1.25˝ in diameter. At the historic structure, each truss is connected via springs.

Accommodating Differential Movement

The vertical atrium wall is entirely dead-loaded back to the new construction by eight tension rods – four inside and four outside – up to 1.25˝ in diameter. At the historic structure, each horizontal kipper truss connects via springs that effectively absorb differential movements between the structures. These trusses and spring details occur every 11´3˝ vertically. The low-iron insulated laminated glass on the vertical facade has two clamp supports 18˝ above and below each truss. This results in an unsupported vertical IGU edge greater than 8´ tall. Stainless steel hanger rods transfer the dead-load back up to the top truss.

Resolving Tension

With the entire vertical wall hung at the top, diagonally and asymmetrically back to the new construction, there are vertical movements that require resolution, especially when interfacing with entrance portals at ground level. The use of stainless steel components draws inspiration from common nautical connection details.

At the bottom horizontal kipper truss, a series of springs – four inside and four outside – effectively absorb this differential movement between the hung and base-loaded elements of the vertical wall. Each spring is nominally 12.5˝ tall coil.

Structural Expression

Enclos was responsible for the architecturally exposed structural steel (AESS) scope and glazing systems for the vertical atrium wall, sloped transition wall, overhead skylight and louver systems that create the 10-story atrium space. Each of these systems spans between an existing historic structure and a newly constructed office building. Achieving the enclosure required coordination of existing anchorage points to the historic structure with diligent surveying, and connection details that permitted differential movements between the old and new structures.

Enclos put its supply chain to work early in the project, with glass coming from Minnesota, aluminum framing fabricated in New York, and steel in New Jersey. Aluminum units were glazed and assembled in a Pennsylvania shop to maximize workmanship in a controlled environment. The glass units were then transported by “wide-load” trucks, escorted near the jobsite and offloaded for just-in-time delivery to accommodate tight construction staging.