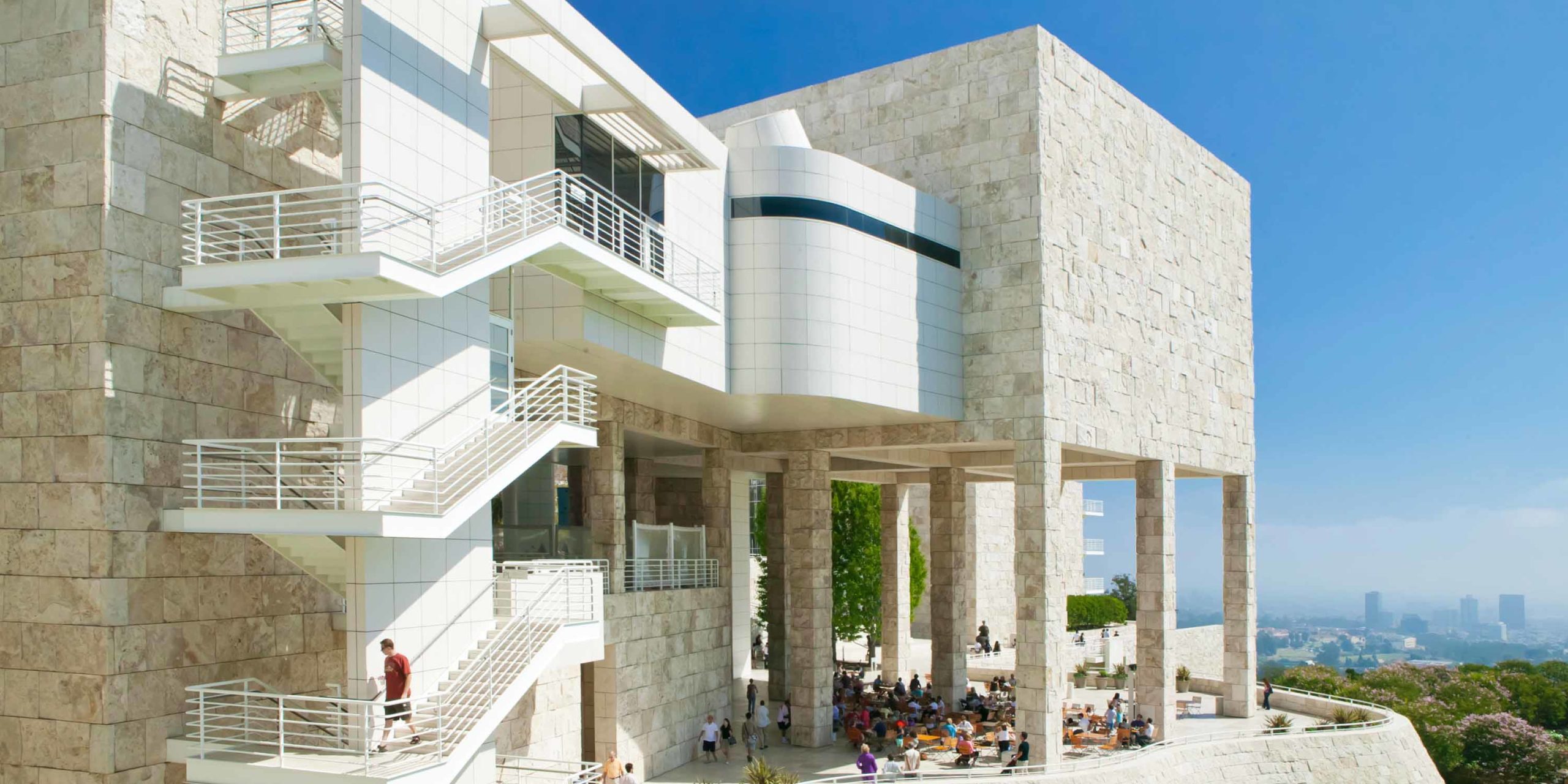

The Getty Center is a $1.2 billion cultural center composed of a 12-building complex overlooking Los Angeles and the Pacific Ocean. The esteemed civic space includes not only a renowned museum but a concert hall, research facility, office complex, and library.

Building Facade Unites Campus of Buildings

By employing modernist facades of glass and travertine stone, Richard Meier & Partners Architects were able to unify the sprawling 24-acre hilltop campus.

Enclos provided comprehensive design/build services for the large and complex facade program. A custom unitized curtainwall system was developed by the Enclos design team, which consisted of more than a dozen designers and engineers dedicated to this unique project. Enclos’ unitized approach allowed for the assembly of large framed units benefiting from factory-controlled conditions, with resulting improvements to both quality and economy. The unitized system also sped installation work.

The Getty campus required 7,116 curtainwall units to skin its exterior. Of these, 4,534 were of different types, each with a highly specific designated location in the facade scheme. Units widths ranged from

Panels and stone conformed to the

The campus houses some of the world’s most valuable and prized artwork and artifacts. For this reason, the building systems were designed with an intended 100-year lifespan. A testing program included three full-scale mockups incorporating each of the various facade system variations used on the project. The Northridge earthquake of 1994 occurred when construction of the museum was well underway, leading to significant design changes in the structures based upon what was learned from the quake damage. The Enclos team responded to the increased seismic requirements in heroic fashion, redesigning all critical interfaces between curtainwall systems and supporting structures in a manner to mitigate the impact of the changes to budget and schedule.

The size and scheduling demands of this massive construction project required Enclos to set up a nearby factory for the assembly of the curtainwall units. Glass, panel materials, and fabricated extrusions converged on the plant from sources far and wide, so great were the material requirements. Well over a million pounds of aluminum extrusions were used as framing elements to construct the units. A tightly knit delivery schedule of units to the site necessitated 592 flatbed trailer loads.

The Getty campus lies nestled alongside two ridges of the Santa Monica Mountains, creating unique site logistics for the construction of the 12 buildings spread out along the site. A one-mile, two-lane road climbed from Interstate 405 to the hilltop above and provided the only access for material delivery. Work crews had to be shuttled to and from the site from a staging area below. The project was divided by Enclos into three phases, each assigned with its own management and field team. As many as eight buildings were in progress simultaneously throughout the build process.

The Getty Center remains an iconic symbol to this day: a city upon a hill, perched above Los Angeles and the Pacific Ocean.