It is an exciting time for the development of advanced facade technology. At the same time, the fundamentals of skilled curtainwall design remain critical.

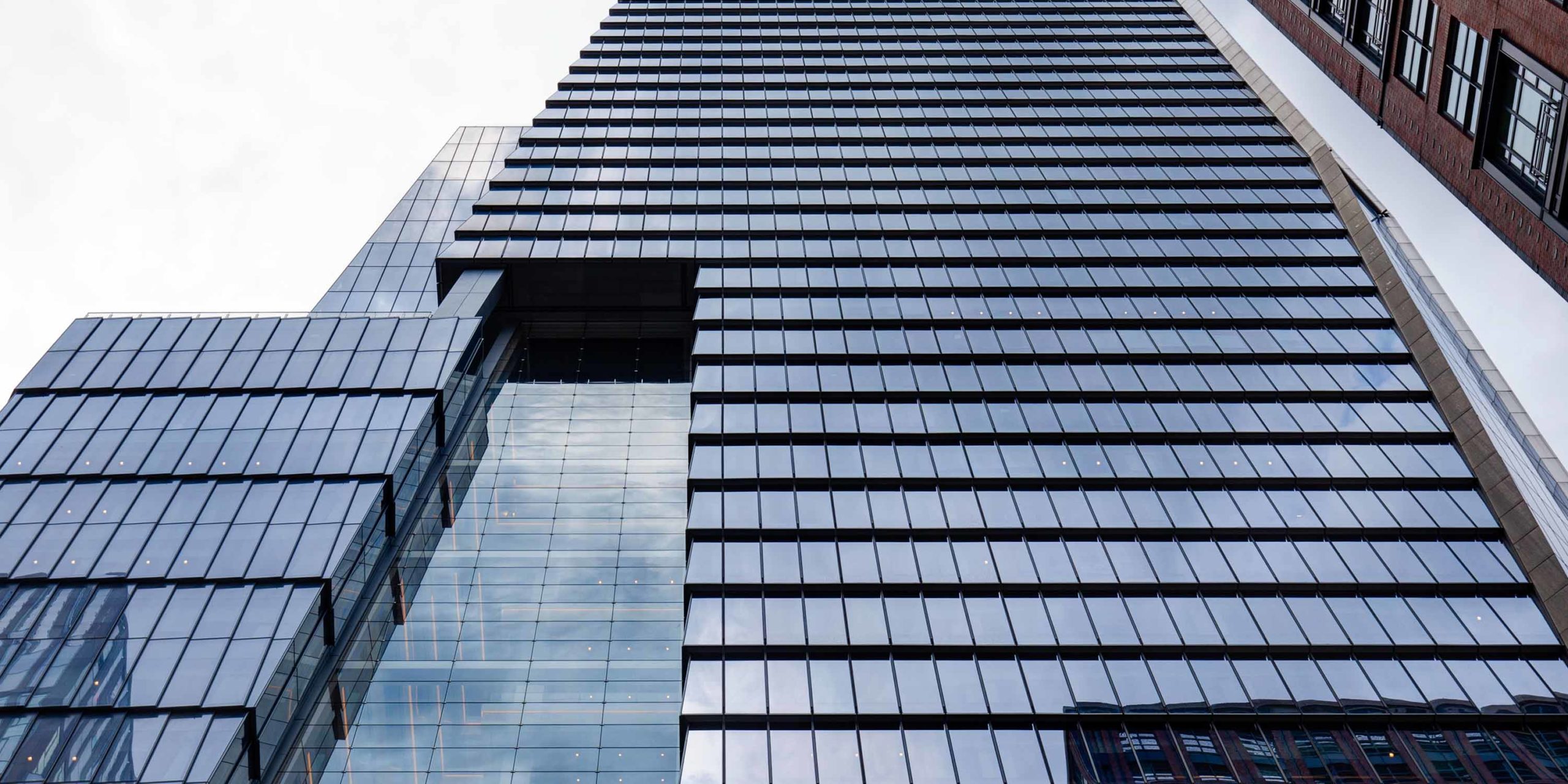

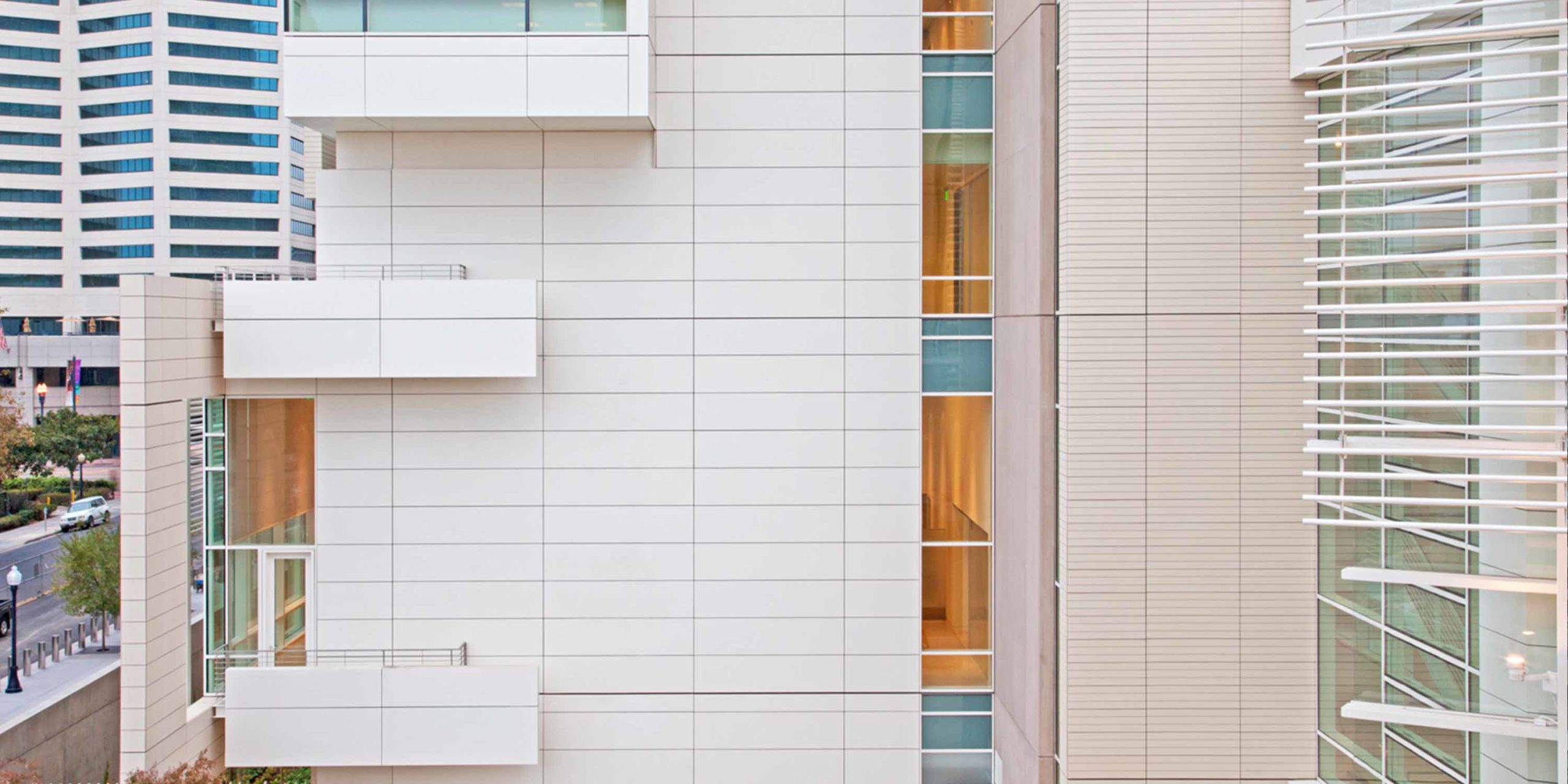

Curtainwall is a prefabricated, modular approach to cladding large buildings. Curtainwall systems are typically “hung” from the building structure (hence the “curtain” reference), attached to the floor slabs, and do not carry any dead loads imposed from the building structure. The units are designed to support their self-weight and to transfer horizontal loads (wind) incident upon them to the primary building structure. Special design considerations can include daylighting, thermal, acoustical, security, and blast-resistant performance. Curtainwall designs for large buildings are almost always custom to individual project requirements.

Performance

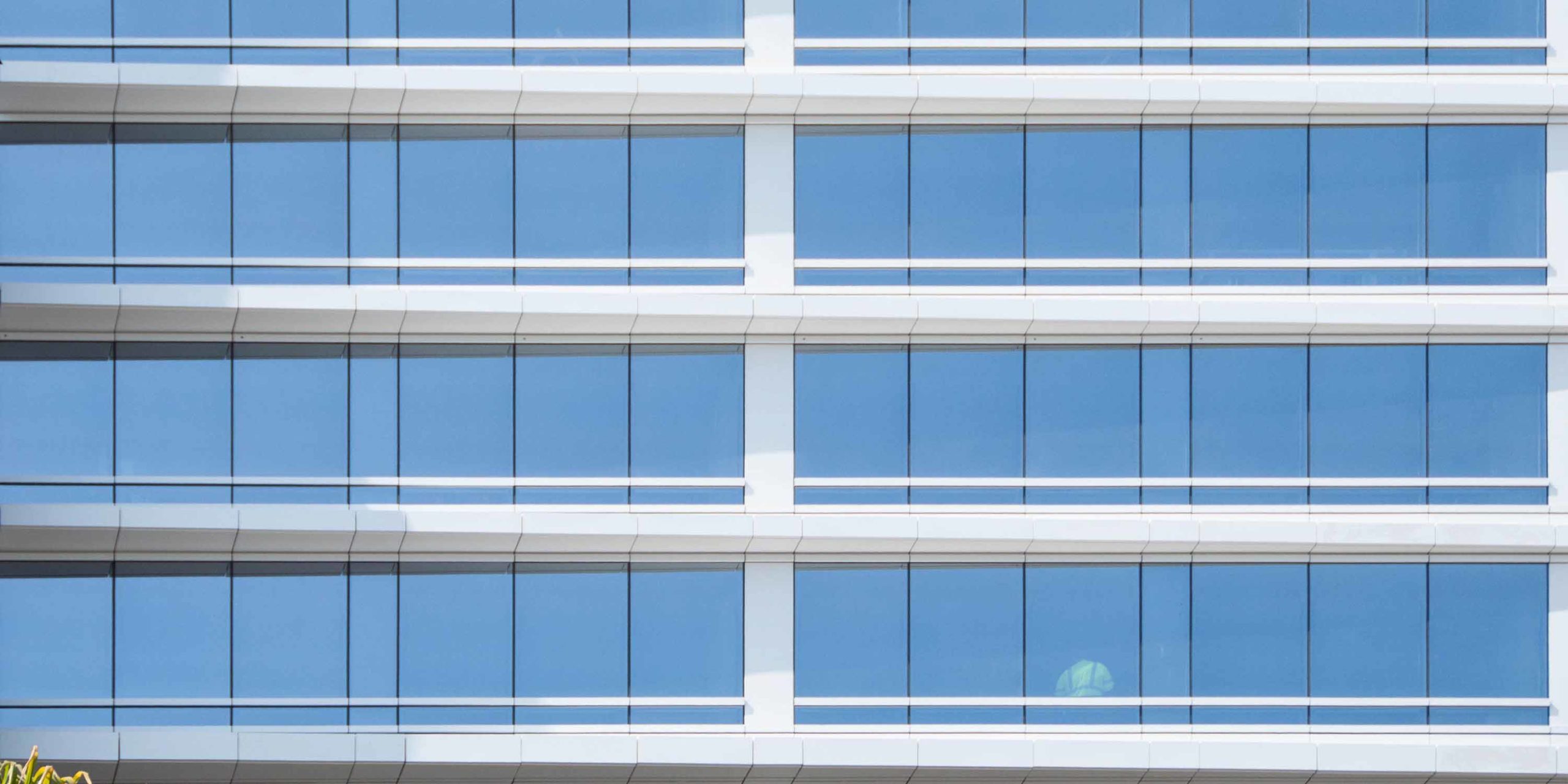

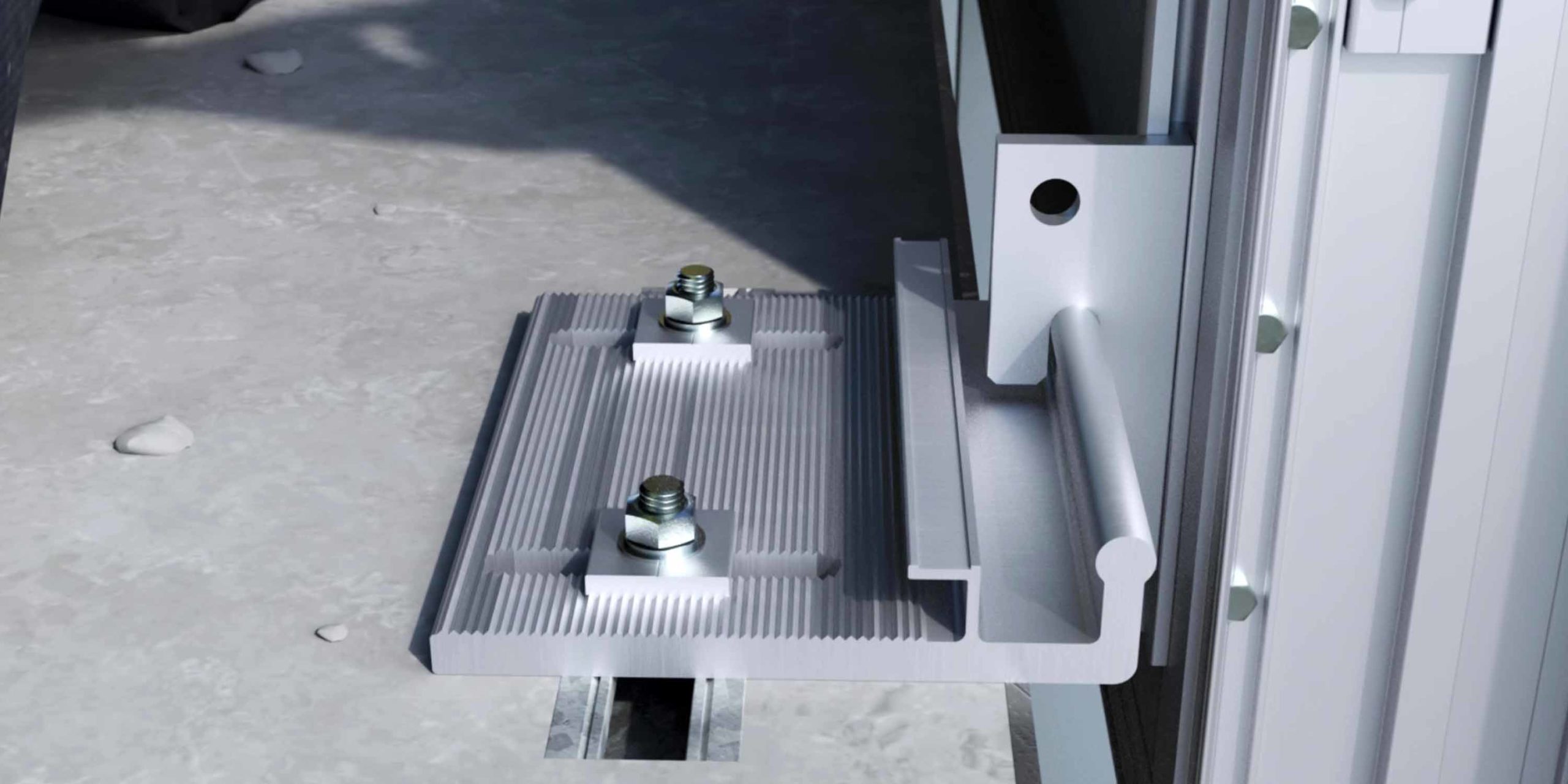

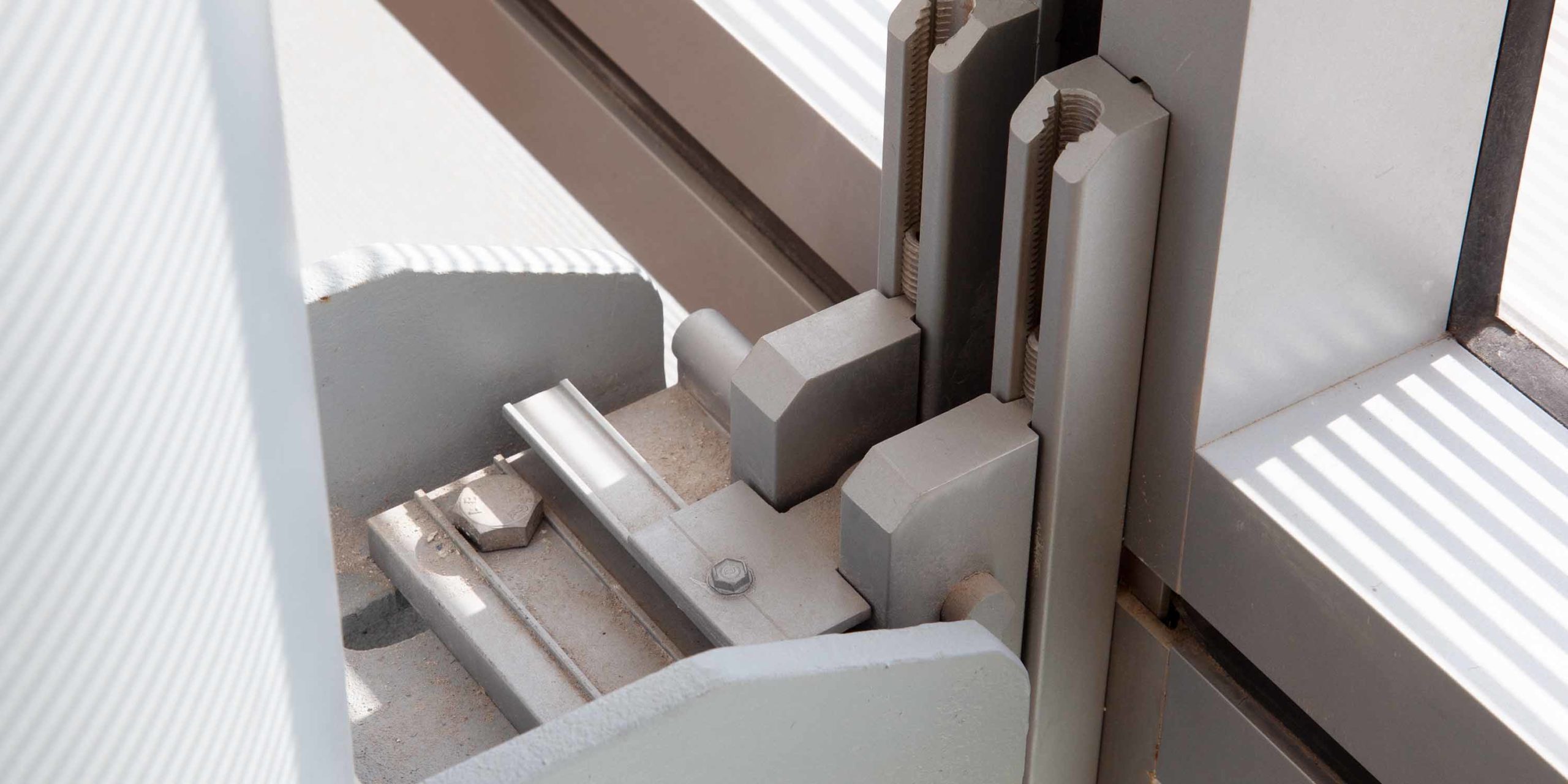

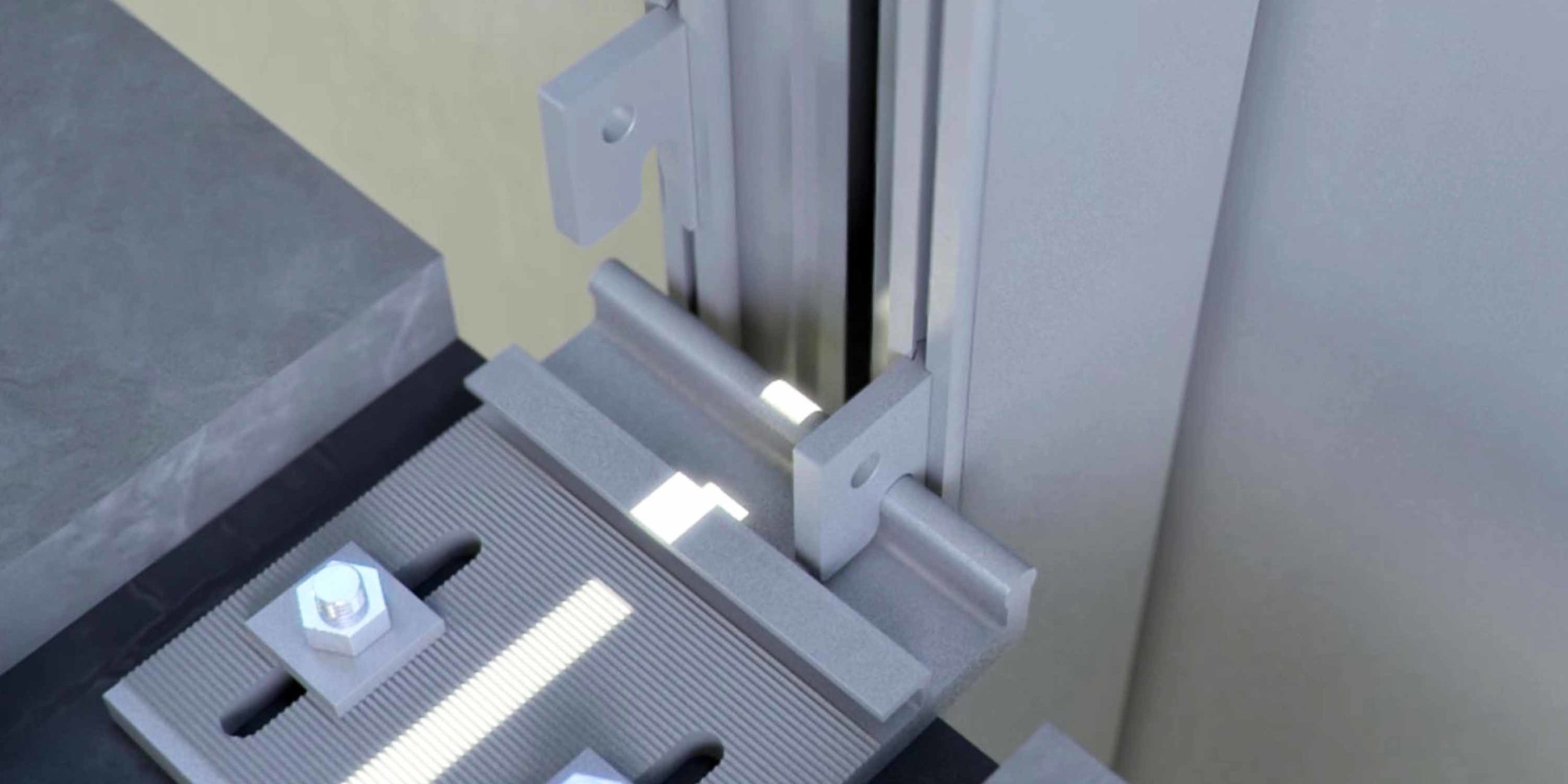

Resisting air and water infiltration is the primary function of the curtainwall, as well as providing a thermal barrier between inside and out. Curtainwall systems are also designed to accommodate the complexities of deflections, thermal expansion and contraction, building sway, and relative movements between floors caused by wind or seismic loads acting on the structure. The convergence of all these performance issues is controlled at what is called the stack joint, the location where one floor of units interlocks with the units above or below. The importance of the stack joint cannot be overstated as it is a crucial performance detail, providing: continuity of air and water resistance; accommodating environmental and building movements; and permitting an efficient, modular installation.

Curtainwall Assembly

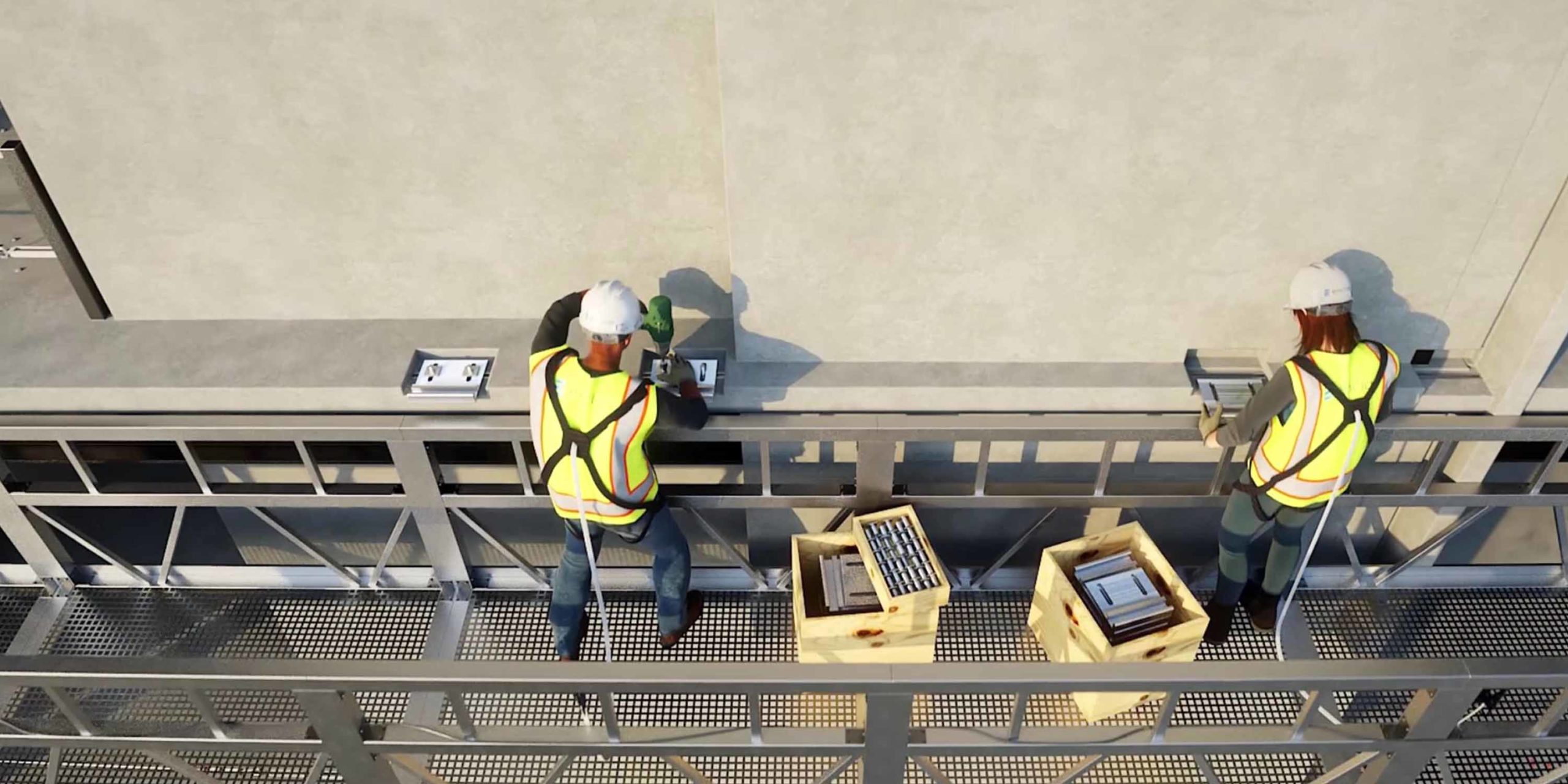

This virtual simulation outlines the procedures that go into assembling a curtainwall frame in a shop environment. The video is one of five in the From Billet to Building educational series.

Framing

Curtainwall designs typically integrate cladding materials that are framed and fixed in place by extruded aluminum components. There are two basic categories of system types, unitized and stick, with the principal difference being where the assembly of the system takes place. The most efficient system type is a unitized system due to its concentration of fabrication and assembly in a controlled factory setting. Whereas, a stick system approach executes all assembly, glazing, and installation in the field. Enclos seeks to maximize the use of unitized systems in part for its ease of installation due to its interlocking, dry-gasketed details between units. That said, there are applications, such as storefronts or specialty structures, where our technical personnel may suggest a stick-built approach.