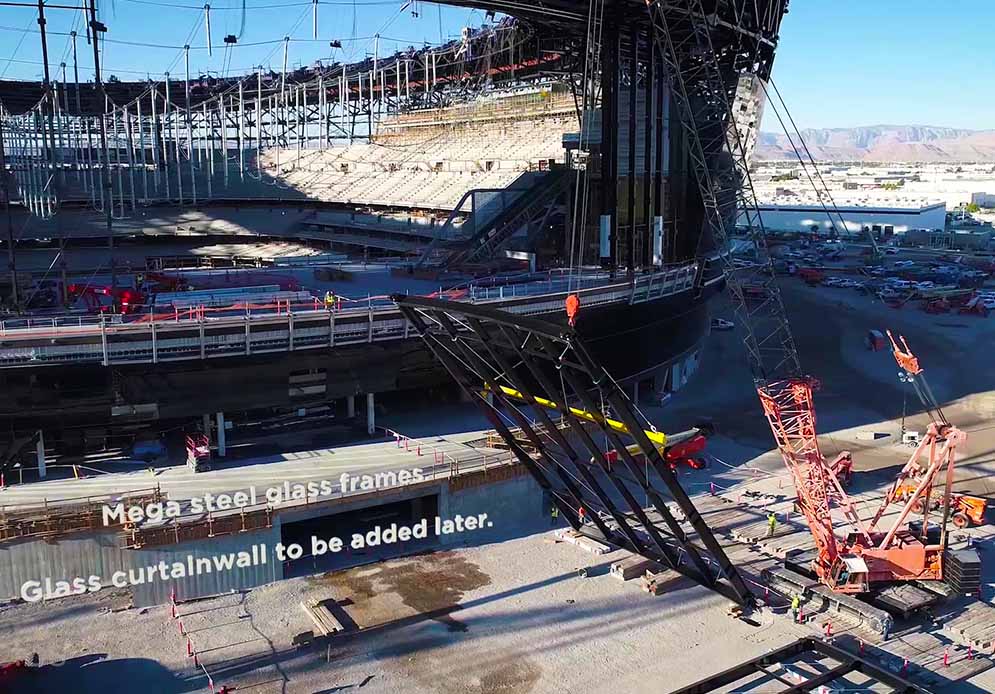

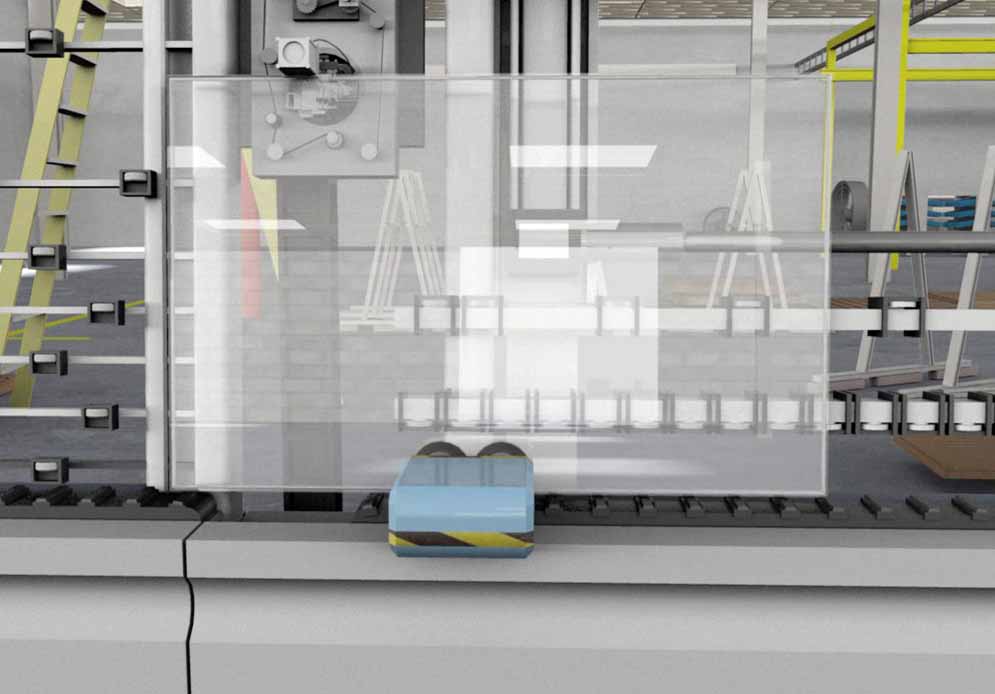

Mega-Kinetics at Allegiant Stadium

The construction of the operable lanai doors at the Las Vegas NFL stadium is showcased. Enclos’ operations and kinetics teams orchestrated a highly coordinated plan to deal with minimal tolerances and clearances. Great work!

read more

High-Performance Design

The number one priority in the facade design is air and water performance. Enclos designers train in maximizing the benefits of unitized systems with the integration of simple, time-tested continuity of air and water barriers while preserving the architectural design intent.

read more

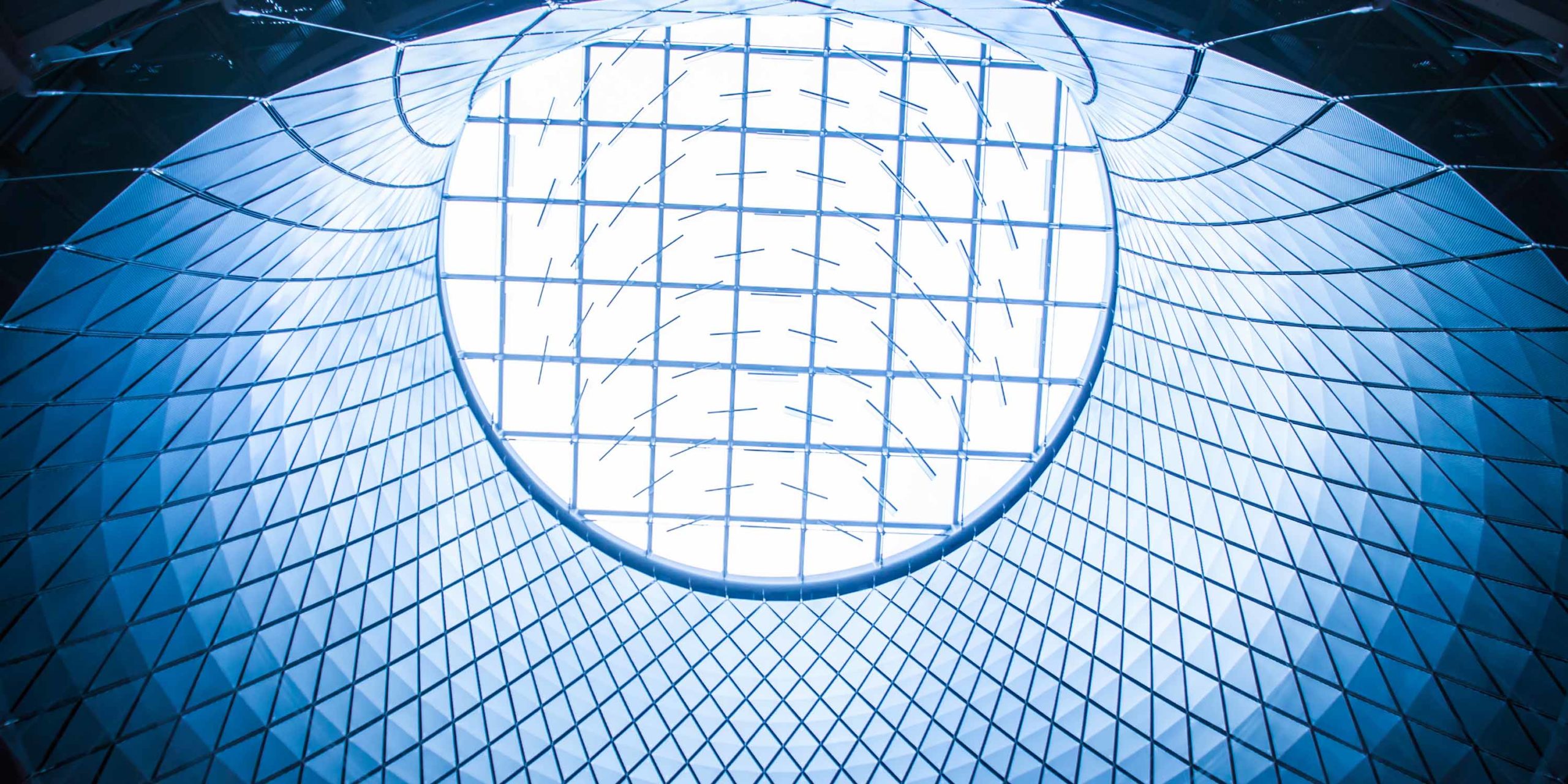

Quality Control of Complex Facade at The Spheres

See how laser scanning technology and custom equipment were used to make the geometrically complex gridshell facade of The Spheres at Amazon a reality.

read more

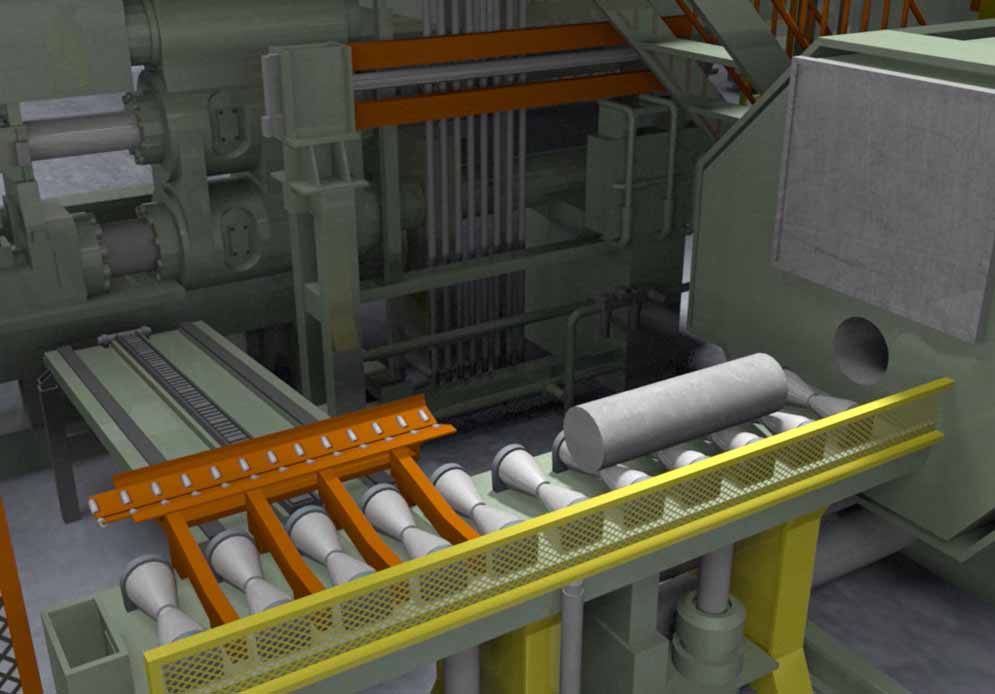

From Billet to Building – Part 1: Manufacture and Fabrication

The construction of high-performance building envelopes is a multi-step process, starting with raw materials such as aluminum billets and glass silica, and results in prefabricated curtain wall unit assemblies that hang from the building structure, most often the floor slabs. This process requires a network of material vendors, processors, fabricators and installers to coordinate diligently. In the five-part video series From Billet to Building, the Advanced Technology Studio of Enclos will animate each step, culminating in several installation strategies.

In Part 4 of From Billet to Building, the multi-step aluminum extrusion manufacturing, fabrication, and finishing processes are showcased, including:

• Aluminum billet to extrusion

• Extrusion stretching

• Paint treatment

• Anodizing treatment

• Part fabrication and machining

Insight 04

In this fourth edition of Insight, the Studio’s multi-disciplinary teams investigate six over-arching themes of complexity, delivery, environmental, material, performance and process — all forces that continue to propel the facade industry forward.

read more

From Billet to Building – Part 2: Float Glass

In Part 2 of From Billet to Building, the glass float process is shown, revealing the linear process that runs through these incredible furnaces, including:

- Raw materials heated to a molten state

- Molten glass floats atop a bath of molten tin before proceeding down the float line

From Billet to Building – Part 3: Insulated Glass Units

In Part 3 of From Billet to Building, the manufacturing process of insulated glass units is presented, including:

- Aluminum spacer is bent into shape

- Spacer is filled with desiccant

- Primary seal is applied to the spacer

- Spacer is placed between two panes of glass

- Unit is then sealed along the edges

From Billet to Building – Part 4: Curtainwall Assembly

In Part 4 of From Billet to Building, the prefabricated assembly process of curtainwall units is visually described, including:

• Insulated glass unit (IGU) installed into an aluminum unit frame

• Sealant quality is carefully documented for Quality Assurance

• Insulated glass units are sealed to the aluminum frame

• Final details attached to the unit frame

• Completed units are bunked for storage while awaiting shipment to project site

From Billet to Building – Part 5: Curtainwall Installation

In Part 5 of From Billet to Building, several on-site installation sequences and strategies for curtainwall are shown, including:

- Unloading of materials on-site, lifting or moving to their designated floors

- Sequence of operations: survey and layout, anchor installation, and curtainwall installation

- Unpack units and prepare for installation

- Attachment of additional components such as sunshades

Ultimately, the site logistics are specific to each project, requiring a carefully coordinated, and crafted, means and methods plan with proper equipment to allow for field crews to operate safely.

read more