By Dave Hughes, BIM Lead

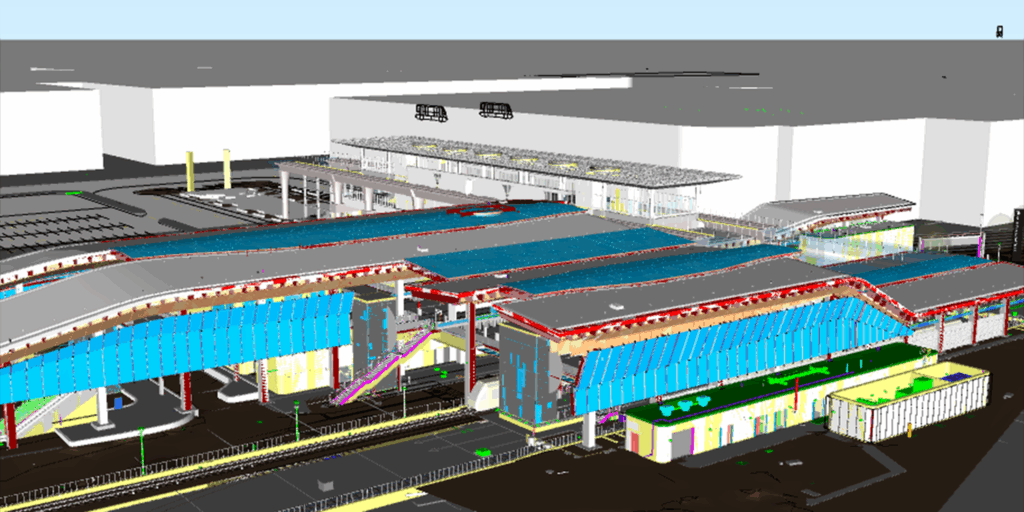

The LAX/Metro Transit Center is the latest addition to the Los Angeles County Metropolitan Transportation Authority (Metro) network, connecting public transit to the Los Angeles International Airport (LAX). The hub provides direct access from the airport to Metro, including light rail connections, a bus plaza, bike hub, vehicle drop-off, customer service center, commercial space, and direct connection to the LAX Automated People Mover (APM). The project is a significant milestone in Los Angeles’ transportation infrastructure, aiming to reduce traffic congestion and promote sustainable travel.

Figure 1: The two-story station provides transfers between public transit and LAX.

Enclos took on the intricate task of constructing the LAX/Metro Transit Center’s 1,044 stainless-steel mesh soffit panels meticulously designed by Grimshaw and Gruen Associates to follow the unique contours of the site and rail lines. To do so, Enclos relied upon integrated parametric modeling and installation techniques.

Project Scope

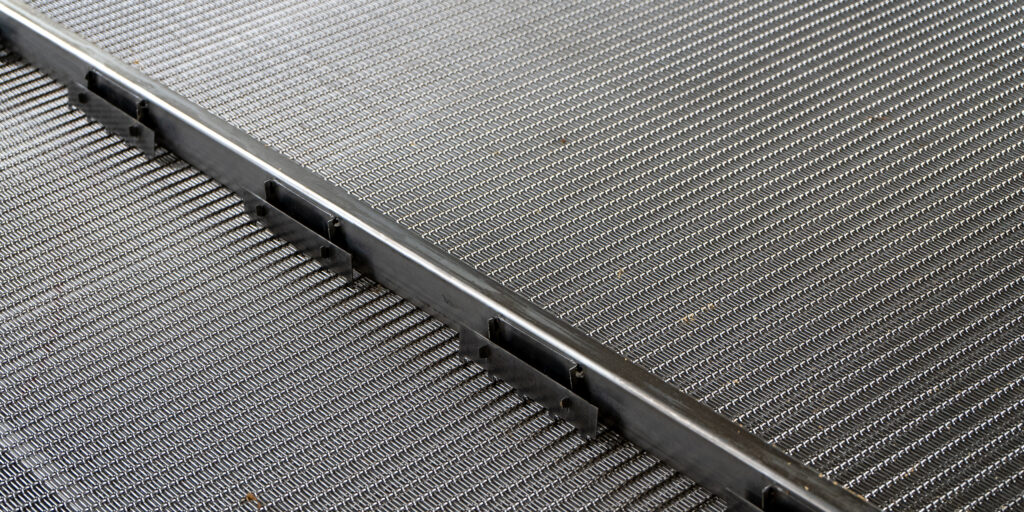

The open-air design of the LAX/Metro Transit Center introduced a unique scope for Enclos. Steel soffit panel frames wrapped in stainless-steel mesh, hanging from the structure with anchors and support rods, create a light, almost floating appearance. While Enclos specializes in curtainwall and weatherproof enclosure systems, the panels are covered by the roof, eliminating the need for weatherproofing. Despite this, the complex design, scale and structural requirements presented numerous challenges in design, manufacturing and installation.

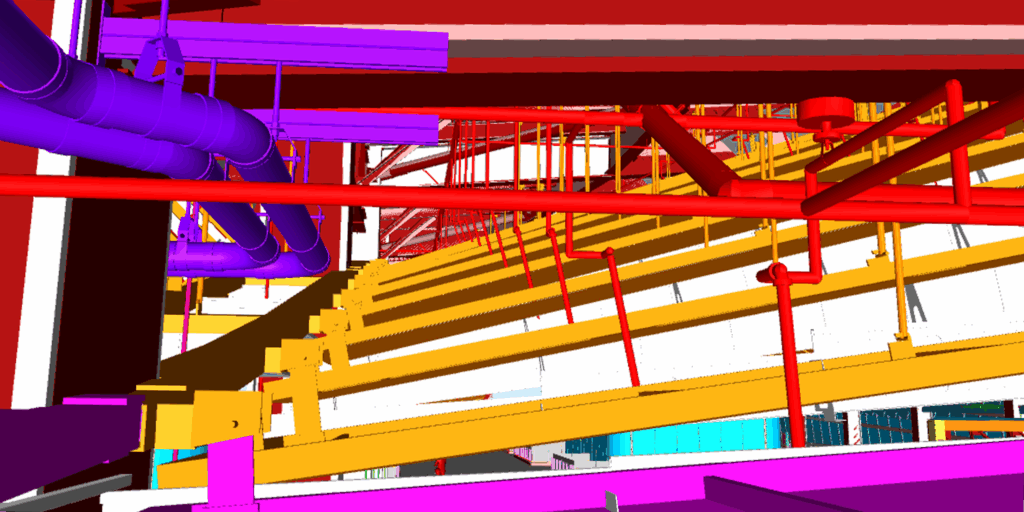

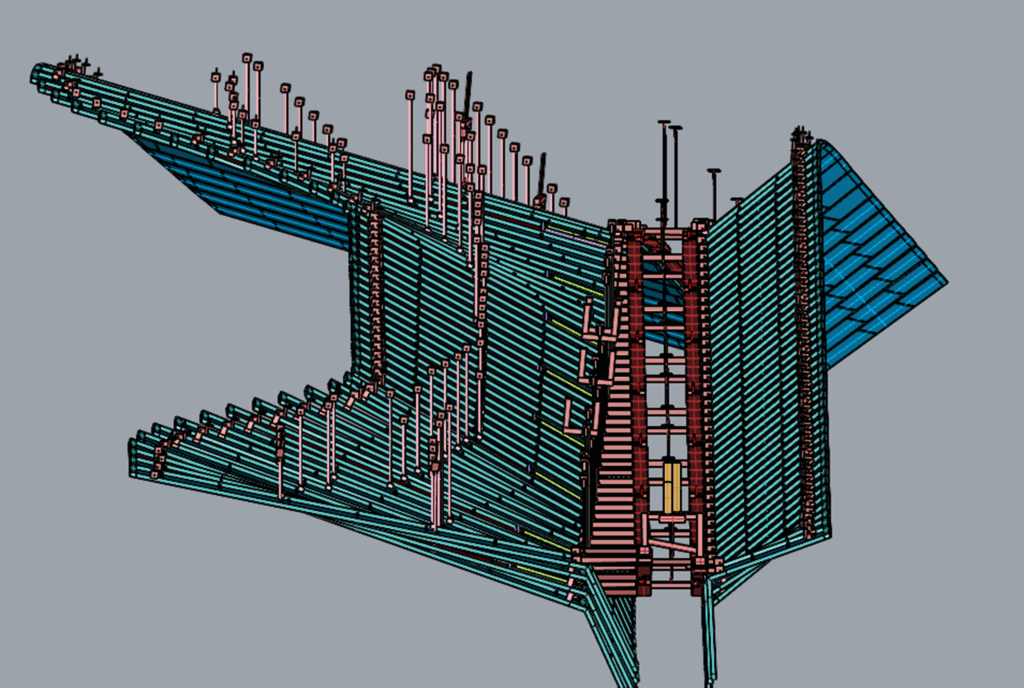

Figure 2: Enclos provided design, engineering, manufacturing and installation services for 78,000 square feet of stainless-steel mesh panels suspended from anchors and support rods.

Using flat panels to accommodate the sweeping design, each varies in length, height and angularity. The smallest panel measures approximately 1-foot-9-inches long, while the largest spans 35 feet long and weighs approximately 1,000 pounds. The panels are attached to varying structural connection points using hooks, requiring a high level of fabrication precision and coordination. Several panels also required access hatches for maintenance crews. Enclos’ kinetics team designed the hatches to meet building code requirements, provide easy and efficient access for maintenance, and maintain the overall panel aesthetic.

Figure 3: Panels range from less than two feet to 35 feet in length.

The design phase involved extensive collaboration between architects, engineers and construction teams to ensure the panels would not only meet aesthetic requirements but also adhere to structural integrity and safety standards. The manufacturing process required precision engineering to fabricate panels that could withstand the environmental conditions and the stresses of installation. The installation phase presented its own set of challenges, including coordinating with other trades, managing tight schedules, and ensuring that each panel was installed accurately.

BIM Coordination & Trade Integration

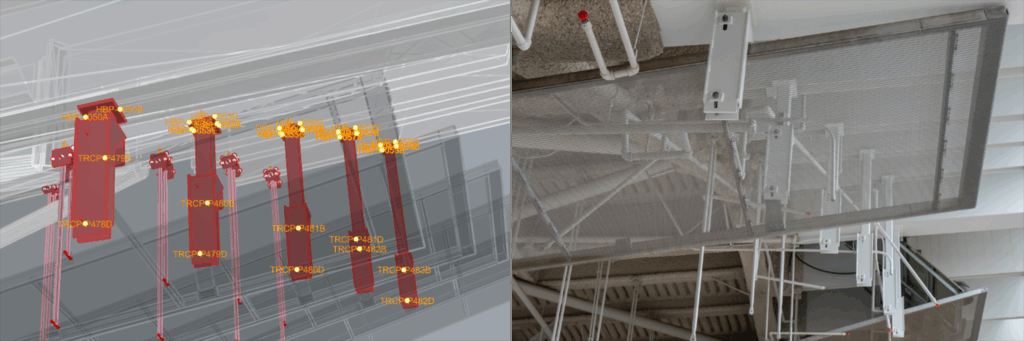

Building Information Modeling (BIM) coordination was crucial for the design and planning of the LAX/Metro Transit Center. Due to the complex structural system, which required connecting Enclos’ anchoring to the same space occupied by mechanical, electrical and plumbing systems, 3D models were used to ensure no two trades conflicted with each other. Weekly coordination meetings were held among a variety of trade partners, playing a key role in the project’s success. The coordination process involved detailed planning and communication among various trade partners, including architects, engineers, contractors and suppliers. BIM allowed for the visualization of the entire project, enabling teams to identify potential conflicts and resolve them before construction began.

Figure 4: 3D modeling and weekly coordination meetings ensured conflicts between trade partners were resolved prior to construction.

This proactive approach minimized delays and ensured the project stayed on schedule. The use of BIM also facilitated systems integration such as heating, ventilation, air conditioning, electrical and plumbing into the overall design. By creating a comprehensive digital model, teams could simulate different scenarios and optimize the placement of components to maximize efficiency and minimize interference. This level of coordination was essential for a project of this scale and complexity.

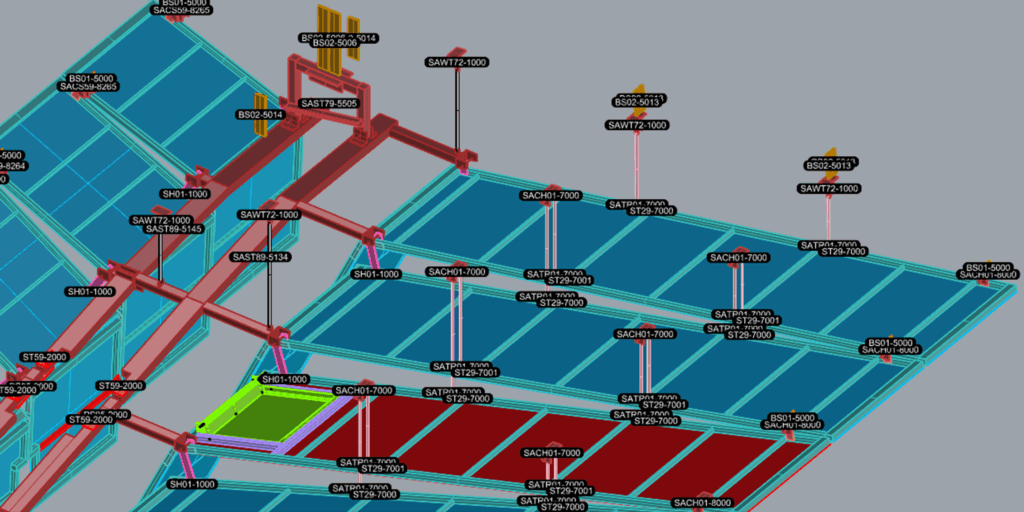

Figure 5: BIM models optimized systems integration into the overall design.

Parametric Modeling

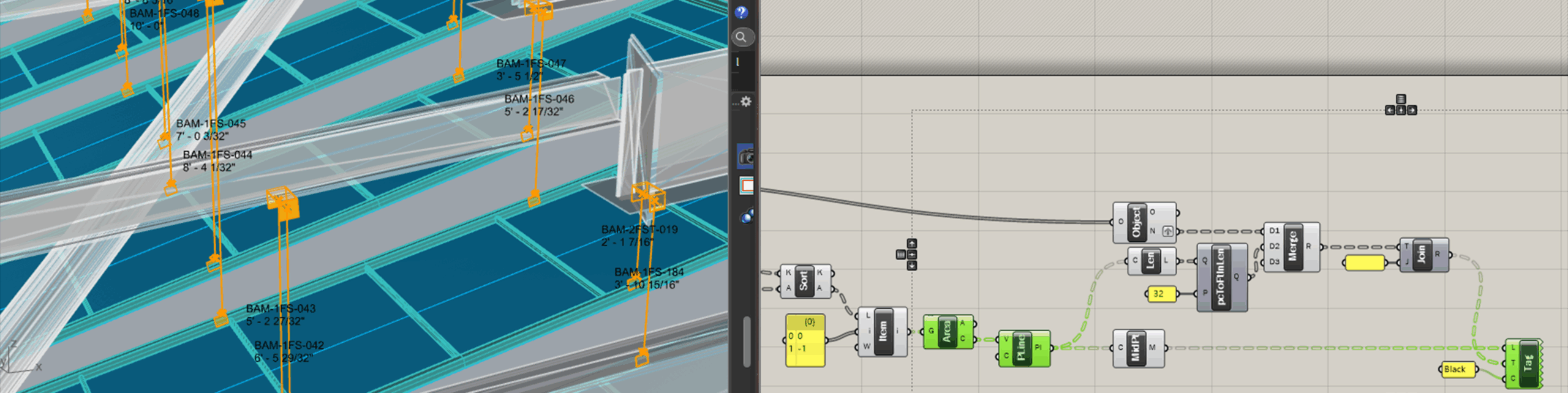

While Enclos is experienced in parametric modeling, this project’s complex form and tight construction schedule necessitated expanding its use. Rhino 3D, paired with the algorithmic plugin Grasshopper, were the primary tools used for modeling. Key data such as panel size, angularity, distance from structure, and reference geometry were extracted from the model en masse to provide the design team with essential information needed to develop system details.

Figure 6: Parametric modeling software was used to determine panel size, angularity and distance from structure.

Once the preliminary design was conceptualized, the structural engineering team developed a series of required parameters for each condition. These parameters were then reincorporated into the model to set all connections. Parametric modeling facilitated the mass production of model elements used for coordination, fabrication and layout. This single model contained more information in one place than any previous Enclos project.

Figure 7: Structural engineering parameters were incorporated into the model for each condition.

The LAX/Metro Transit Center pushed Enclos’ capabilities, requiring the firm to create new modeling techniques to increase efficiency, accuracy, and overall utilization of 3D models in construction. The integration of advanced parametric modeling allowed for real-time adjustments and optimizations, ensuring that design and construction processes were both streamlined and highly precise. By leveraging the power of digital tools, Enclos was able to deliver a high-quality product that met demanding requirements of the project.

Figure 8: New modeling techniques streamlined the station’s precise design and construction requirements.

Global Sourcing

GKD Metal Fabrics fabricated and assembled the soffit panels, wrapping them in specialty stainless-steel mesh. Galvanized support rods were procured from Macalloy in the United Kingdom, and all other anchor connections were fabricated by Trussworks International (TWI) in California. With suppliers located around the world, parametric modeling ensured accuracy, which was paramount in the procurement and production of the nearly 20,000 parts required to create the soffit panels.

Figure 9: A global supply chain manufactured nearly 20,000 parts for the station’s soffit panel system.

Each vendor brought specialized expertise and high-quality materials that contributed to the overall success of the The LAX/Metro Transit Center. GKD Metal Fabrics’ experience in fabricating complex metal-mesh structures ensured that the soffit panels met stringent design and performance criteria. Macalloy’s support rods provided necessary strength and durability to support panels, while TWI’s anchor connections ensured secure and precise installation.

The global nature of the supply chain required careful coordination and communication to ensure that all components arrived on time and met the required specifications. The use of parametric modeling facilitated this process by providing accurate and detailed information to vendors, enabling them to produce parts that fit seamlessly into the overall design.

3D Layout & Digital Surveying

Due to panels being hung from the structure with varying degrees of height and angularity on three axis, traditional layout methods using a simple tape measure were obsolete. Electronic Trimble total station surveying equipment was required to locate all anchors. Points were placed in the 3D model at every anchor and labeled. The XYZ coordinates and labels were extracted from the model and fed into the total station, which relayed the points on-site, allowing the field team to place anchors in the precise locations required. There was little leeway, so the project could not have succeeded without using advanced technology.

Figure 10: Coordinates were extracted from the 3D model and entered into surveying equipment to precisely place anchors on-site.

The layout process was a critical phase of project, requiring precision and accuracy to ensure that each panel was installed correctly. The Trimble total station provided the necessary technology to achieve this level of precision by translating digital coordinates into physical locations on-site. This technology allowed the field team to work efficiently and accurately, minimizing errors and ensuring that panels were installed according to design specifications.

The use of advanced surveying equipment also facilitated integrating different systems, such as electrical and plumbing, into overall layout. By providing accurate coordinates, the total station ensured that all components were placed correctly, avoiding conflicts and optimizing the use of space.

Panel Installation

Even with the aid of the total station, installation presented numerous challenges. The tight construction schedule required multiple trades to work in the same areas simultaneously. For the upper structure and panels, scaffolding — known as the “dancefloor” — was constructed to give the field crew direct access to the structure without the need for lifts.

Figure 11: Scaffolding was erected for field crews to install the upper structure and panels.

While the added access was a significant improvement, it introduced a new challenge of hoisting panels into place. A rig was created to hoist panels up to the dancefloor, where they were then hooked to the anchors. This rigging system, known as the “tugger,” was designed to handle the weight and size of panels, ensuring that they could be lifted safely and securely. The installation process required careful planning and coordination to ensure that each panel was placed accurately and securely.

Figure 12: Enclos’s field team developed a unique rigging system to lift panels safely and securely.

The installation phase also involved extensive collaboration between different trades, including electricians, plumbers and HVAC technicians. By working together, these teams were able to integrate their systems into the overall design, ensuring that panels were installed correctly and that all components functioned as intended.

Project Takeaways

The LAX/Metro Transit Center exemplifies the successful integration of parametric modeling, meticulous coordination, and advanced construction techniques. The innovative approaches adopted by Enclos not only met the project’s complex requirements but also set a new standard for future construction endeavors. The collaborative efforts and technological advancements demonstrated in this project highlight transformative potential of digital tools in the construction industry.

The success of the The LAX/Metro Transit Center underscores the importance of embracing innovative technologies and collaborative approaches in modern construction. By leveraging advanced digital tools and fostering strong partnership coordination, the construction industry can achieve new levels of efficiency, accuracy and sustainability. The lessons learned and benchmarks set by the project will undoubtedly influence future projects, paving the way for continued advancements in the field.